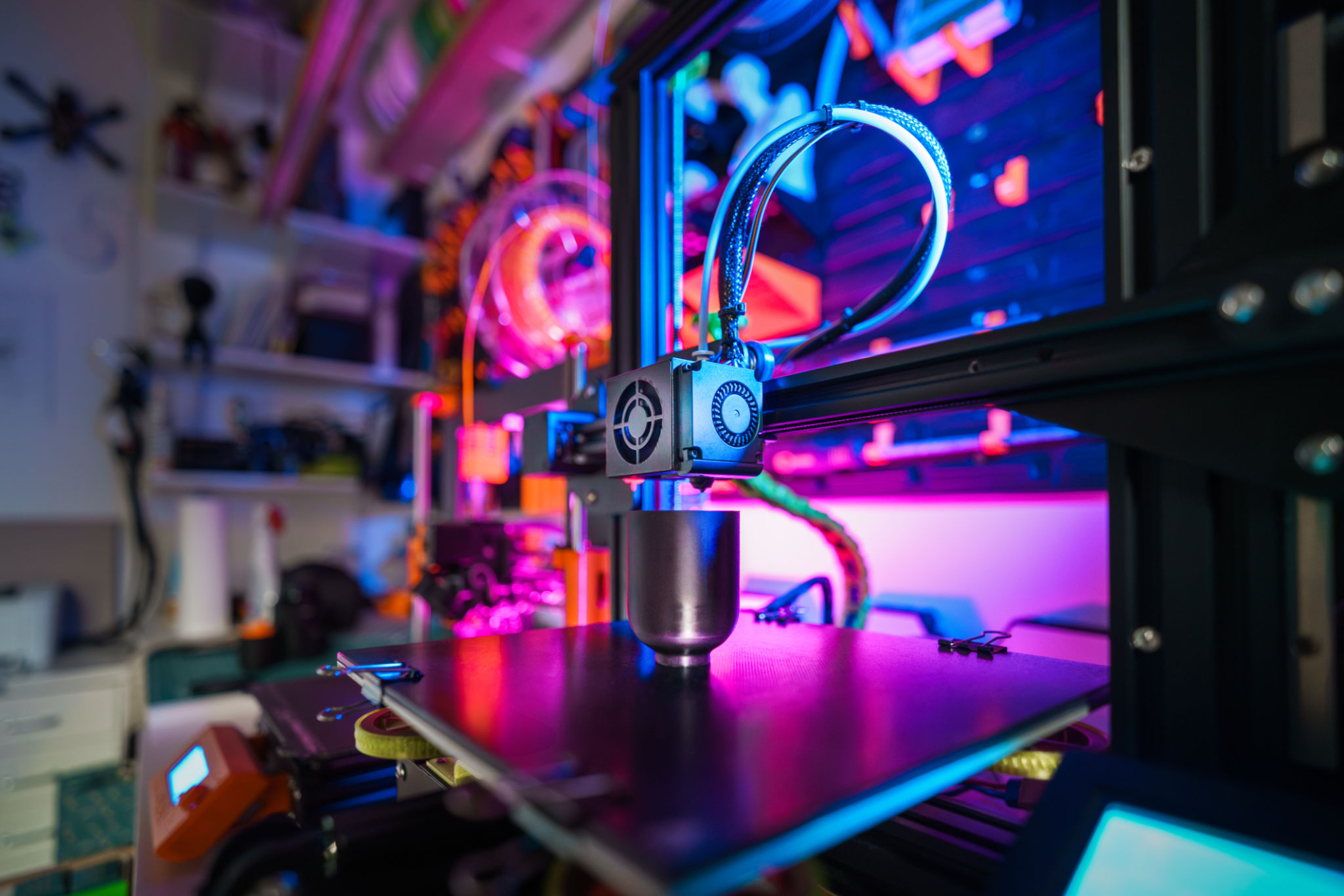

Low Volume 3D Printing: The Perfect Solution for End Use Parts

Understanding Low Volume 3D Printing

In recent years, 3D printing technology has transformed from a prototyping tool into a viable solution for creating end-use parts. The advent of low volume 3D printing has opened new avenues for industries seeking to produce parts with precision and efficiency. This method allows businesses to meet demands without the large-scale production commitments traditionally required.

Low volume 3D printing offers flexibility in manufacturing, as it accommodates customized designs and rapid modifications without significant cost increases. This capability is particularly beneficial in industries such as aerospace, medical devices, and automotive, where specific requirements and standards are critical.

The Benefits of Low Volume 3D Printing

Cost-Effectiveness

One of the main advantages of low volume 3D printing is its cost-effectiveness. Traditional manufacturing processes often involve expensive tooling and molds, which can be prohibitive for small-scale production. By eliminating these costs, businesses can produce high-quality parts at a fraction of the price.

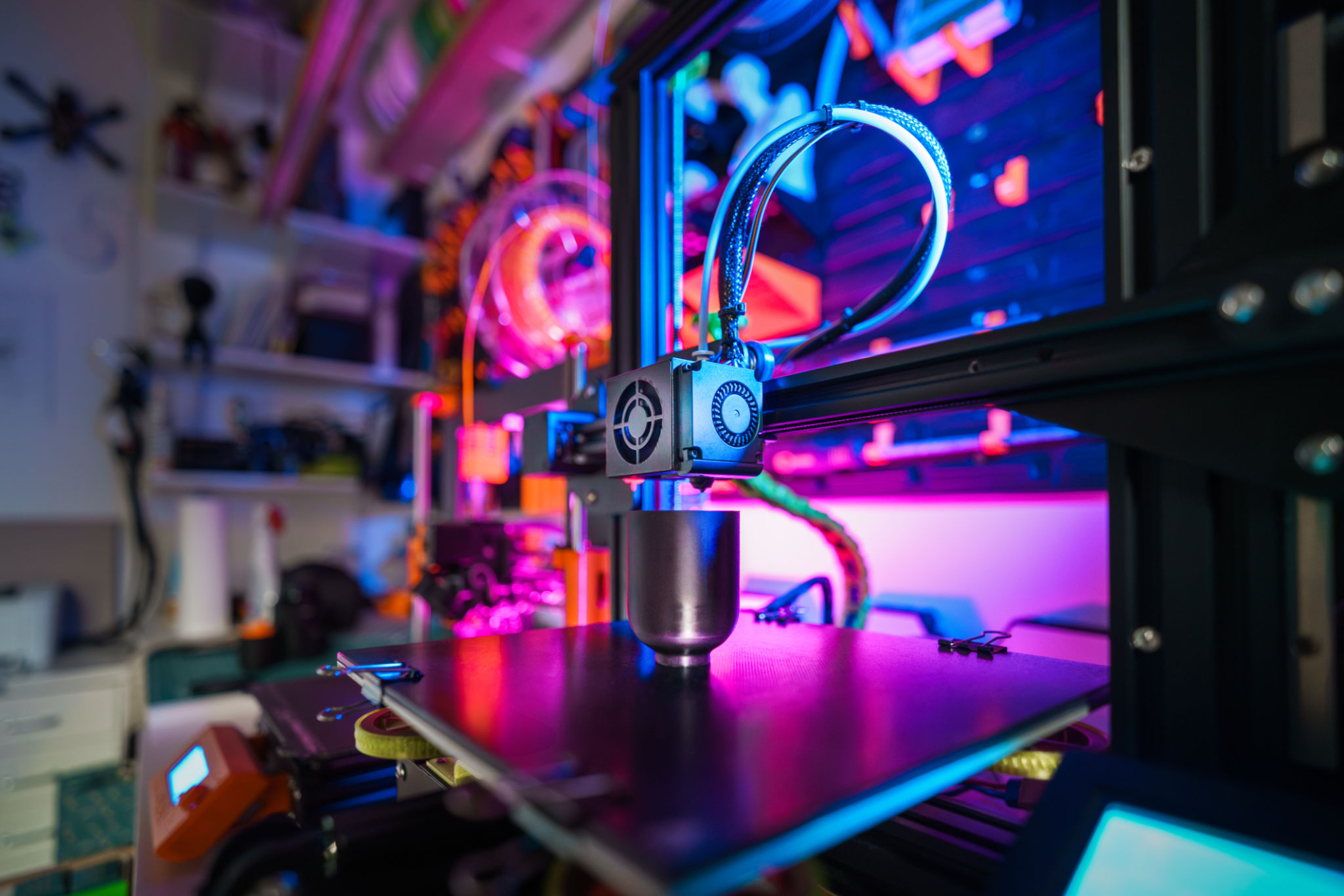

Speed and Agility

3D printing allows for rapid production cycles. With the ability to go from design to finished product in a matter of days, companies can bring their products to market faster. This speed is complemented by the agility to make design changes on the fly, ensuring that the final product meets all specifications and standards without lengthy delays.

Applications Across Industries

Aerospace and Defense

In the aerospace and defense sectors, precision and reliability are paramount. Low volume 3D printing provides a solution that meets these needs by producing complex parts with tight tolerances. The technology also allows for lightweight designs, which are crucial in these industries.

Medical Devices

The medical field benefits greatly from the customization capabilities of 3D printing. From prosthetics to surgical tools, low volume production enables the creation of patient-specific devices that improve outcomes and comfort. Additionally, the rapid prototyping capability aids in the swift development of innovative medical solutions.

The Future of Manufacturing

As technology continues to evolve, low volume 3D printing is poised to play an increasingly important role in manufacturing. It offers a sustainable solution by minimizing waste and reducing the carbon footprint associated with traditional manufacturing methods. The ability to produce on-demand also contributes to a more efficient supply chain.

Looking ahead, advancements in materials and technology will further enhance the capabilities of 3D printing, enabling even more applications across various industries. Companies that embrace this technology will undoubtedly gain a competitive edge by delivering high-quality products quickly and efficiently.

Conclusion

Low volume 3D printing is reshaping the landscape of manufacturing by providing an innovative solution for producing end-use parts. Its cost-effectiveness, speed, and customization potential make it an ideal choice for industries requiring precision and adaptability. As adoption grows, we can expect to see even more exciting developments in how products are designed and manufactured.