Case Study: Successful Aerospace Prototyping with 3D Printing in South Elgin

Introduction to Aerospace Prototyping with 3D Printing

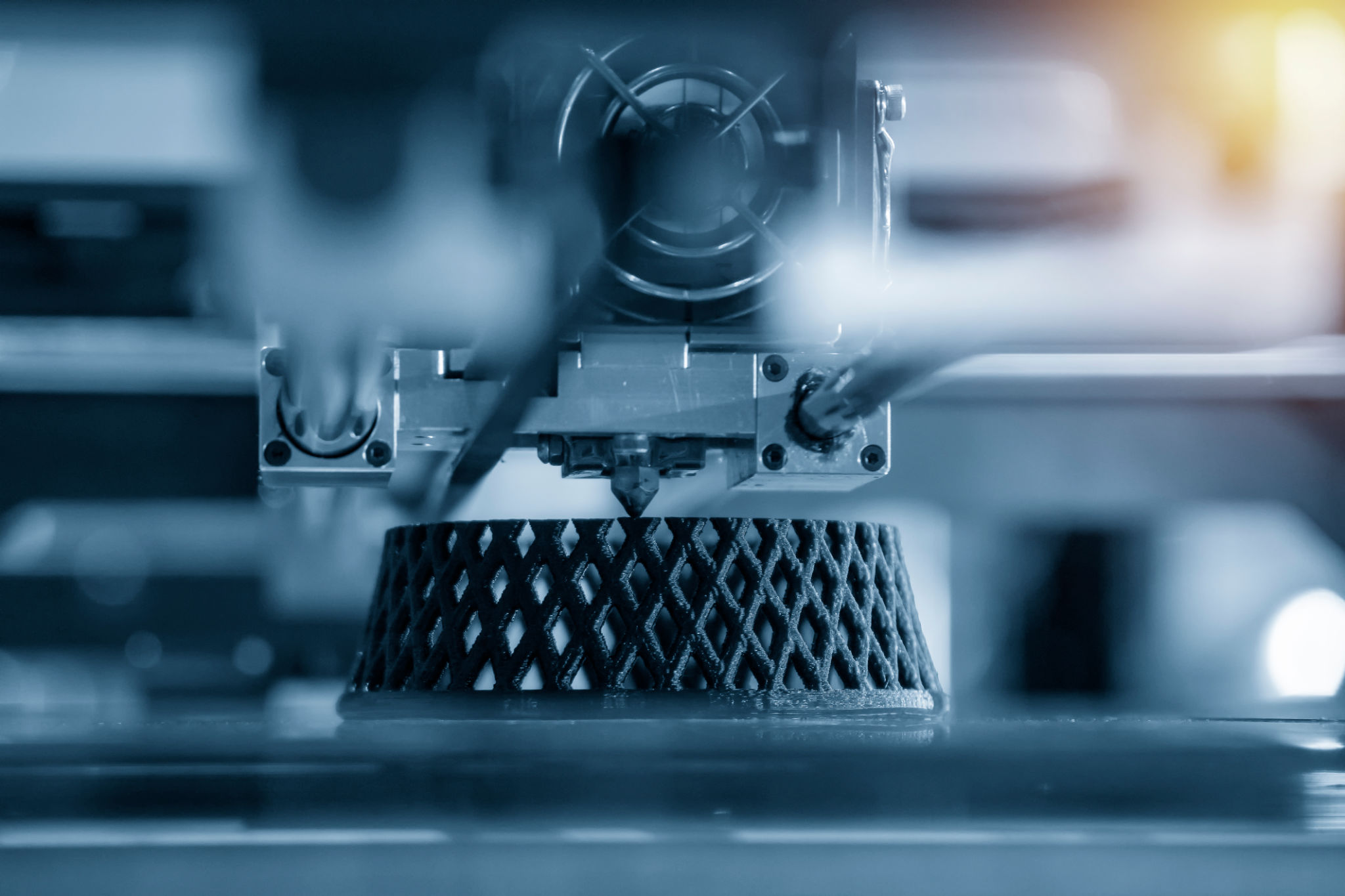

In recent years, South Elgin has become a hub for innovation in the aerospace industry, particularly in the realm of prototyping. One of the most groundbreaking advancements aiding this progress is 3D printing technology. By leveraging this cutting-edge technology, companies have been able to drastically reduce lead times and costs associated with traditional manufacturing methods.

The impact of 3D printing on aerospace prototyping cannot be overstated. This technology allows for rapid iteration, enabling engineers to test multiple designs quickly. As a result, aerospace companies in South Elgin are not only keeping pace with global competitors but setting new standards for efficiency and innovation.

Key Benefits of 3D Printing in Aerospace

The adoption of 3D printing within the aerospace sector in South Elgin has brought numerous benefits. First and foremost, it significantly reduces production time. Traditional manufacturing methods often involve lengthy processes, but 3D printing allows for faster prototyping and production.

Additionally, 3D printing reduces material waste, which is a crucial consideration in aerospace manufacturing. The layer-by-layer construction used in 3D printing ensures that only the necessary amount of material is used, contributing to both cost savings and environmental sustainability.

Customization and Flexibility

Another significant advantage of 3D printing is the level of customization it offers. Aerospace components often require precise specifications unique to each project. With 3D printing, engineers can easily customize parts to meet exact requirements without the need for costly retooling.

Case Study: A Leading Aerospace Company in South Elgin

A leading aerospace company in South Elgin recently embarked on a project utilizing 3D printing for developing advanced prototypes. The company focused on creating lightweight yet durable components, a key factor in improving fuel efficiency and performance.

By integrating 3D printing into their prototyping process, the company achieved remarkable success. They reported a reduction in lead times by up to 50% and a decrease in production costs by nearly 30%. These impressive figures underscore the transformative impact of 3D printing on their operations.

Challenges and Solutions

While the benefits of 3D printing are clear, the technology is not without its challenges. One common issue faced by companies is ensuring the strength and durability of printed components. The aerospace industry demands high-performance parts that can withstand extreme conditions.

To address these challenges, companies in South Elgin have invested in research and development to improve material properties and printing techniques. By collaborating with material scientists and engineers, they have developed innovative solutions that ensure printed components meet rigorous aerospace standards.

The Future of Aerospace Prototyping in South Elgin

The success of 3D printing in aerospace prototyping has set a new benchmark for innovation in South Elgin. As technology continues to advance, we can expect even more sophisticated applications that further enhance efficiency and performance.

Looking ahead, the collaboration between local companies and academic institutions will play a crucial role in driving forward new research and development initiatives. This synergy will ensure that South Elgin remains at the forefront of aerospace innovation, with 3D printing as a key enabler.

Ultimately, the integration of 3D printing into aerospace prototyping represents a significant leap forward for the industry. As companies continue to explore and refine this technology, they are paving the way for a future where rapid innovation and sustainability are at the core of aerospace manufacturing.