Choosing the Right Material: A Guide to Engineering-Grade 3D Printed Parts

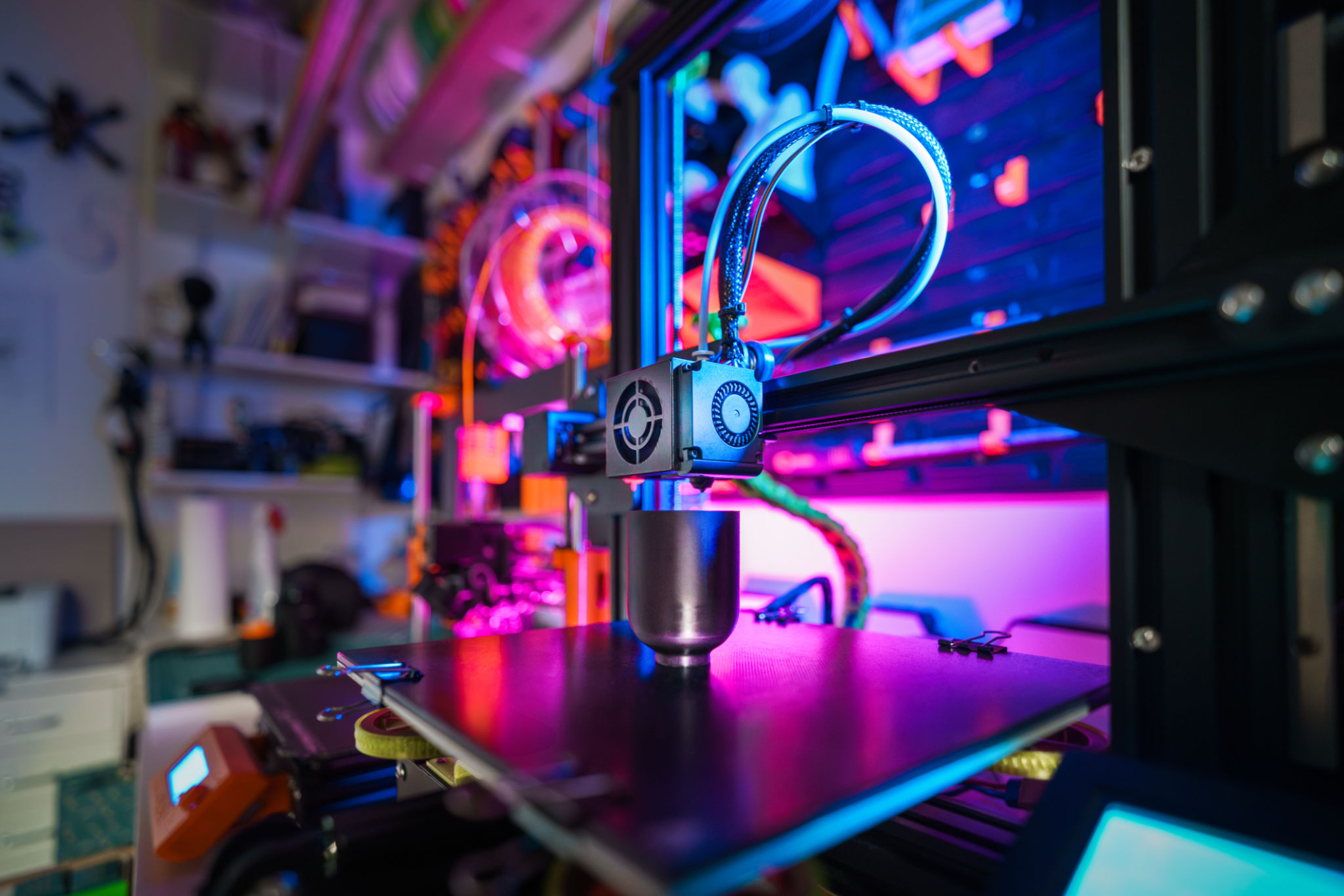

Introduction to Engineering-Grade 3D Printing

3D printing has revolutionized the way industries approach manufacturing, allowing for rapid prototyping and production of complex parts. When it comes to engineering-grade 3D printed parts, choosing the right material is crucial to ensure durability, function, and performance. With a variety of materials available, understanding their properties can help you select the best option for your project.

Understanding Material Properties

Different materials offer distinct characteristics that can affect the final product's strength, flexibility, and thermal resistance. Engineering-grade materials often include plastics, metals, and composites, each with unique benefits. It's essential to consider the specific requirements of your application when selecting a material.

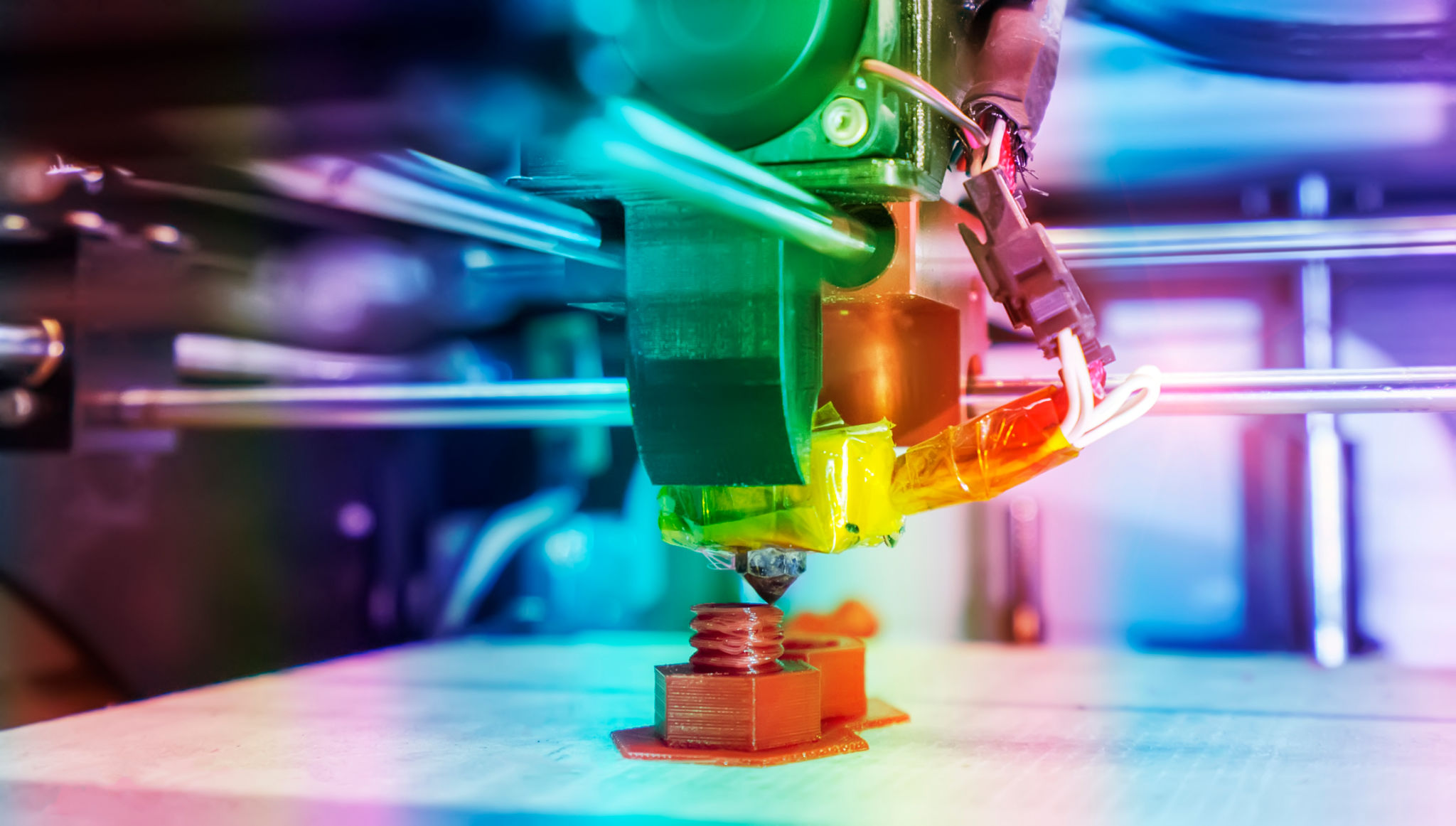

Plastic Options

Plastics are the most commonly used materials in 3D printing due to their versatility and cost-effectiveness. Popular options include:

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength and impact resistance, ideal for functional parts.

- PLA (Polylactic Acid): Biodegradable and easy to print with, suitable for prototypes.

- Nylon: Offers excellent mechanical properties and resistance to wear, perfect for durable parts.

Metal Materials

For applications requiring high strength and thermal resistance, metal 3D printing is an excellent choice. Commonly used metals include:

- Aluminum: Lightweight and corrosion-resistant, ideal for aerospace and automotive industries.

- Titanium: Extremely strong with a high strength-to-weight ratio, used in medical and high-performance applications.

- Stainless Steel: Offers excellent strength and durability, suitable for a wide range of applications.

Composite Materials

Composite materials combine the strengths of different substances to offer enhanced properties. They are perfect for specialized applications where standard materials might fall short. Options like carbon fiber-reinforced polymers provide exceptional strength and stiffness while remaining lightweight.

Factors to Consider When Choosing Materials

When selecting a material for engineering-grade 3D printing, consider the following factors:

- Mechanical Properties: Evaluate strength, flexibility, and durability.

- Thermal Resistance: Consider the operating environment's temperature requirements.

- Chemical Resistance: Ensure compatibility with any chemicals the part might be exposed to.

- Cost and Availability: Balance performance with budget constraints.

Conclusion: Making the Right Choice

Selecting the appropriate material for engineering-grade 3D printed parts is a critical step in the design process. By understanding the unique properties of each material and considering the specific needs of your project, you can make informed decisions that lead to successful outcomes. Whether you choose plastics, metals, or composites, each material offers distinct advantages that can enhance the functionality and performance of your 3D printed parts.