Common Misconceptions About 3D Printing in Manufacturing

Understanding 3D Printing in Manufacturing

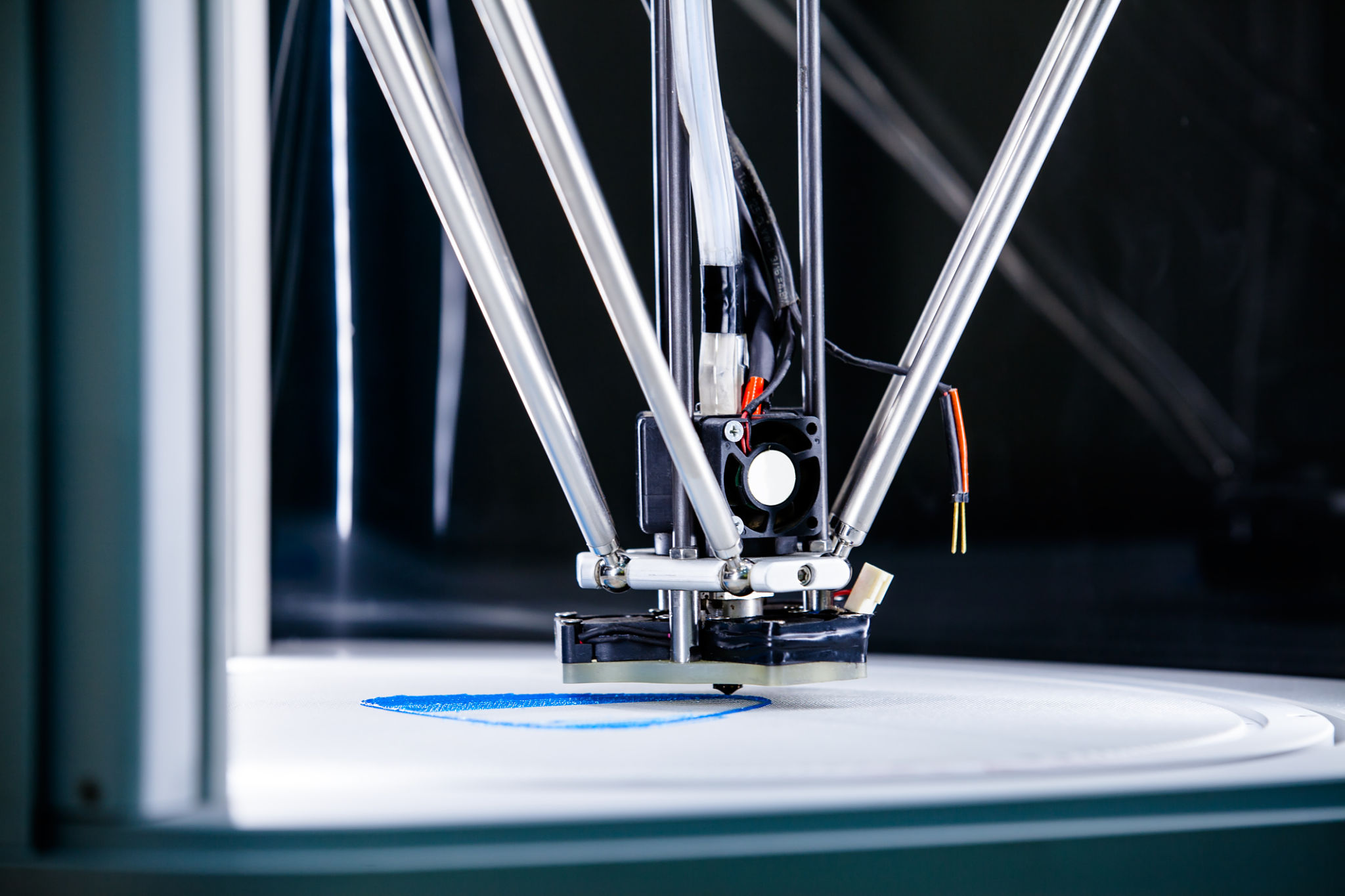

3D printing, also known as additive manufacturing, has been making waves in the manufacturing industry. However, despite its growing popularity, there are several misconceptions that continue to persist. Clearing up these misunderstandings can help businesses better leverage this innovative technology.

One common misconception is that 3D printing is only suitable for prototyping. While it's true that 3D printing excels at creating prototypes quickly and efficiently, its applications extend far beyond this single use. Many industries are now using 3D printing for small to medium production runs, custom parts, and even end-use products.

3D Printing is Not Just for Plastic

Another prevalent myth is that 3D printing can only work with plastic materials. In reality, modern 3D printers can work with a wide variety of materials, including metals, ceramics, and even food. This versatility makes it possible to create complex components for industries such as aerospace, automotive, and healthcare.

Manufacturers can choose from various materials depending on their specific needs. For instance, metal 3D printing is excellent for creating durable and heat-resistant parts, while biocompatible materials are used extensively in the medical field for implants and prosthetics.

Cost-Effectiveness of 3D Printing

Many businesses assume that 3D printing is prohibitively expensive compared to traditional manufacturing methods. However, for certain applications, 3D printing can actually be more cost-effective. This is especially true when producing small batches or highly customized products where traditional tooling and setup costs would be high.

Additionally, the ability to produce parts on-demand reduces inventory costs and allows for greater flexibility in production schedules. This flexibility can lead to significant savings over time, particularly for companies that experience fluctuating demand or require rapid product iterations.

Speed and Efficiency of Production

It's a common belief that 3D printing is a slow process, unsuitable for large-scale manufacturing. While it may not yet match the speed of some traditional production lines for large quantities, 3D printing can be surprisingly fast for smaller batches and complex designs. The technology has been continually improving, with newer machines offering faster print speeds and larger build volumes.

The efficiency of 3D printing also lies in its ability to consolidate multiple parts into a single assembly. This reduces the need for additional assembly processes and can significantly cut down on production time and labor costs.

Quality and Durability Concerns

Lastly, there is a misconception that 3D printed parts are inherently weaker or lower in quality compared to traditionally manufactured parts. While early versions of 3D printing had limitations, advancements in technology have greatly improved the strength and quality of printed components.

Today’s 3D printers offer high precision and accuracy, producing parts that meet or exceed industry standards. Quality control processes have also evolved, ensuring that 3D printed products maintain consistency and reliability across batches.

In conclusion, understanding and dispelling these misconceptions is crucial for businesses considering the adoption of 3D printing technologies. By embracing the true capabilities of 3D printing, manufacturers can explore new possibilities in design, production, and innovation.