Common Misconceptions About FDM 3D Printing Services

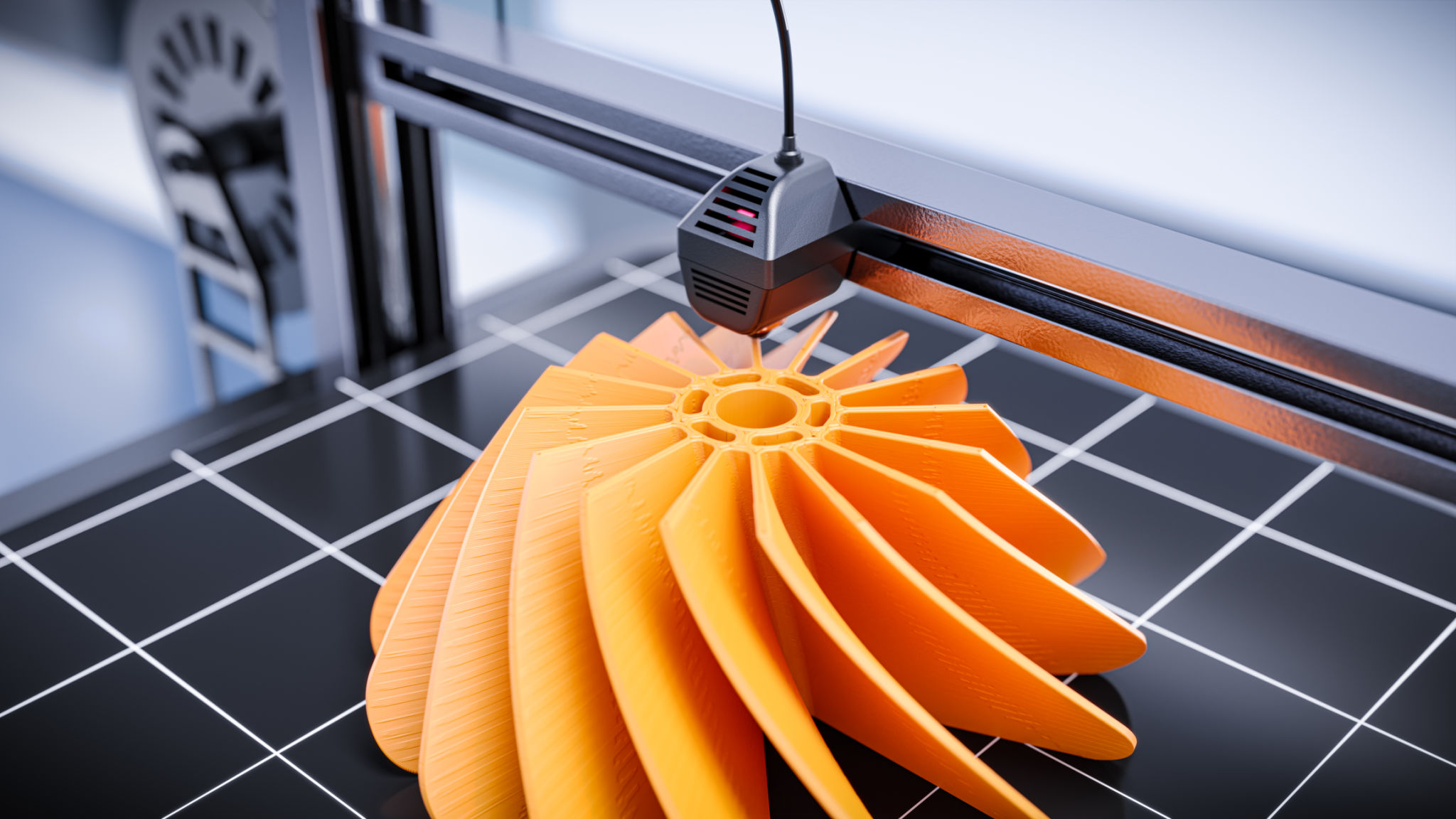

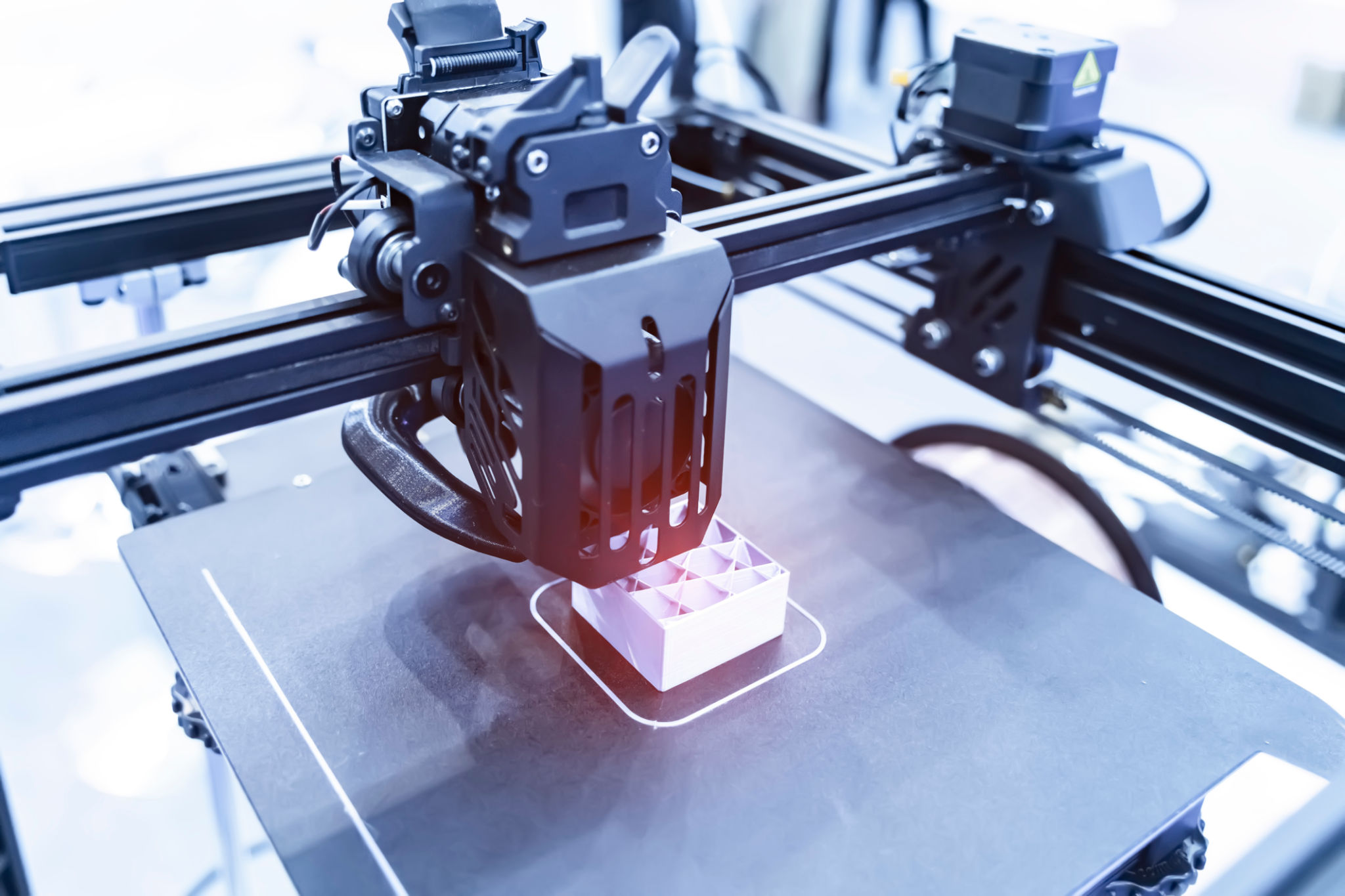

Understanding FDM 3D Printing

Fused Deposition Modeling (FDM) is one of the most popular 3D printing technologies used today, especially in prototyping and small-scale production. Despite its widespread use, there are several misconceptions about FDM 3D printing services that can lead to misunderstandings about its capabilities and limitations. By shedding light on these myths, we can better appreciate the value and potential of FDM technology.

Myth 1: FDM Printing is Only Suitable for Prototyping

One common misconception is that FDM 3D printing is only suitable for creating prototypes. While it's true that FDM is widely used for prototyping due to its cost-effectiveness and speed, it can also be utilized for end-use parts and products. The advancements in materials and printer technology have expanded its application to include functional testing and even small batch production. Industries such as aerospace, automotive, and medical are increasingly adopting FDM for these purposes.

Moreover, FDM printers can use a wide variety of thermoplastic materials, each with unique properties that can be tailored to specific applications. This versatility makes FDM a viable option for creating durable and functional parts beyond just prototypes.

Myth 2: FDM Printed Parts Lack Strength

Another myth surrounding FDM technology is that the parts it produces are inherently weak. While it's true that the layer-by-layer nature of FDM can introduce anisotropy, where strength varies in different directions, this issue can be mitigated through careful design and orientation during printing. By optimizing print parameters and using high-quality materials, it's possible to produce strong and reliable parts.

Additionally, advancements in composite materials, such as carbon-fiber reinforced thermoplastics, have significantly increased the mechanical properties of FDM-printed parts. These materials offer enhanced strength and stiffness, making them suitable for demanding applications.

Myth 3: FDM Printing is Inaccurate

A misconception often heard is that FDM printing lacks precision compared to other 3D printing technologies. While FDM may not always match the accuracy of technologies like Stereolithography (SLA) or Selective Laser Sintering (SLS), it can still produce highly accurate parts with fine details. The key is understanding the capabilities of the specific printer being used and selecting appropriate settings for the desired outcome.

Modern FDM printers come with improved hardware and software that allow for better resolution and finer detail reproduction. Additionally, post-processing techniques such as sanding, polishing, or chemical smoothing can further enhance the surface finish and dimensional accuracy of FDM printed parts.

Myth 4: FDM Printing is Slow

Many people believe that FDM printing is inherently slow, making it unsuitable for time-sensitive projects. However, this is not always the case. The speed of an FDM print depends on several factors including layer height, infill density, and print settings. By optimizing these parameters, it's possible to significantly reduce print times without compromising quality.

Moreover, new developments in printer technology have introduced faster print heads and more efficient motion systems that allow for quicker production times. For urgent projects, it's important to work closely with a knowledgeable service provider who can adjust settings to meet deadlines effectively.

Conclusion

In conclusion, while there are many misconceptions about FDM 3D printing services, a deeper understanding reveals its true potential and versatility. By debunking these myths, we can better appreciate how FDM technology fits into the broader landscape of additive manufacturing and take advantage of its benefits for various applications. As technology continues to evolve, so too will the capabilities and efficiencies of FDM 3D printing.