Comparing 3D Printing Materials: Which is Best for Your Project?

Understanding 3D Printing Materials

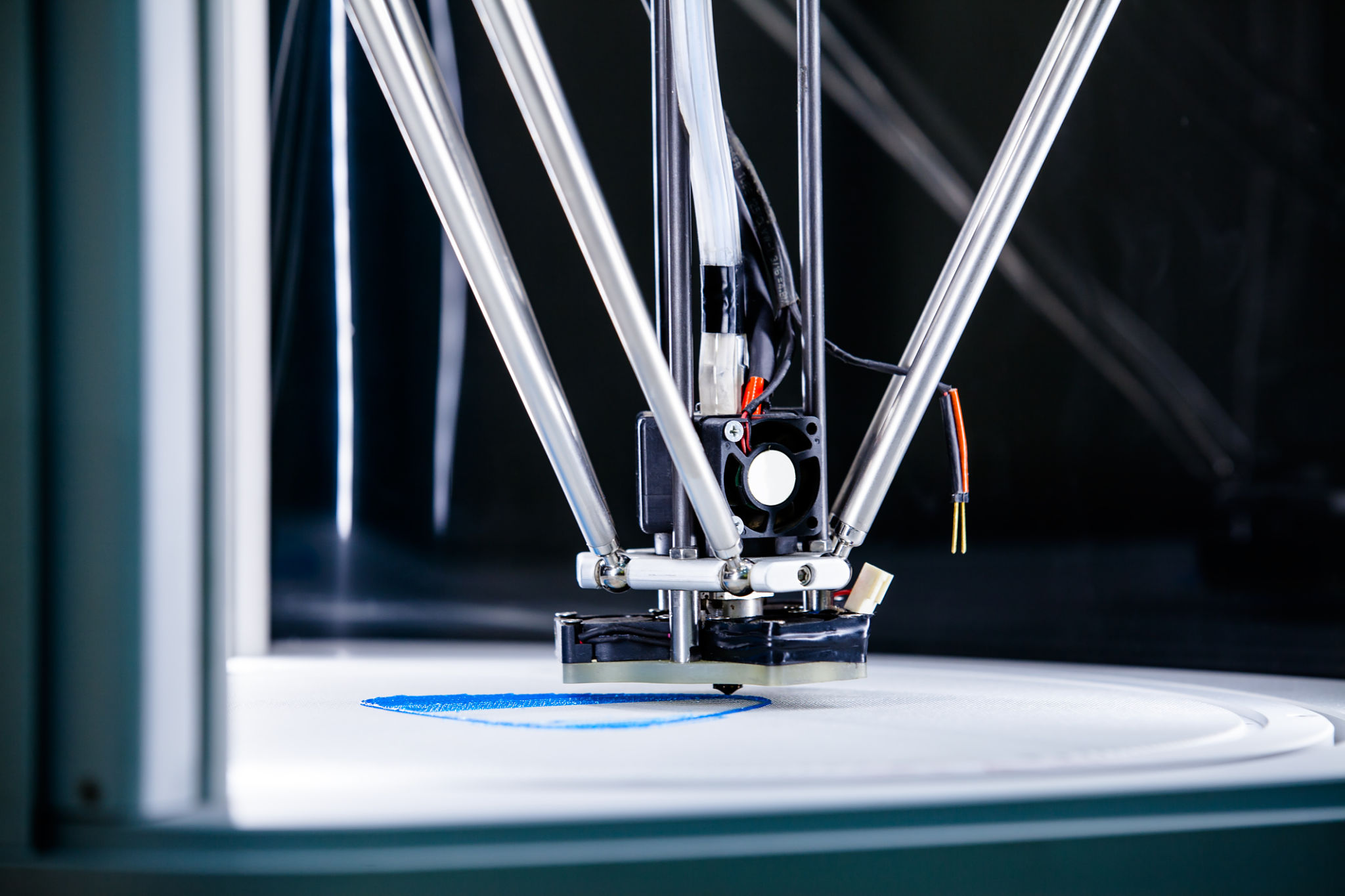

As the 3D printing industry continues to evolve, choosing the right material for your project becomes increasingly crucial. Whether you're creating prototypes, functional parts, or artistic models, the material you select will influence the quality, durability, and functionality of your final product. Let's explore some of the most popular 3D printing materials and their unique attributes to help you make an informed decision.

PLA: The Beginner's Choice

Polylactic Acid (PLA) is one of the most commonly used materials in 3D printing, especially favored by beginners. It is a biodegradable thermoplastic derived from renewable resources like corn starch. PLA is known for its ease of use and versatility, making it ideal for a wide range of applications. However, it's important to note that PLA is not very heat-resistant and may not be suitable for projects that require exposure to high temperatures.

Advantages of PLA:

- Biodegradable and environmentally friendly

- Available in a wide range of colors

- Low warping tendency

ABS: Strong and Durable

Acrylonitrile Butadiene Styrene (ABS) is another popular choice, known for its strength and durability. It is commonly used in automotive parts, toys, and electronic housings. ABS is more heat-resistant than PLA, making it suitable for more demanding applications. However, it requires a heated print bed and can emit fumes during printing, so adequate ventilation is essential.

Advantages of ABS:

- High strength and impact resistance

- Better thermal stability compared to PLA

- Can be easily post-processed with acetone for a smooth finish

Nylon: Flexibility and Resilience

Nylon is a versatile material known for its flexibility, resilience, and wear resistance. It is often used for creating functional and mechanical parts due to its excellent mechanical properties. Nylon's flexibility makes it ideal for parts that need to be bent or twisted without breaking. However, printing with nylon can be challenging due to its tendency to absorb moisture from the air.

Advantages of Nylon:

- High strength and durability

- Excellent abrasion resistance

- Good flexibility and impact resistance

Specialty Materials: Expanding Possibilities

Beyond the basic materials, there are specialty options like TPU (Thermoplastic Polyurethane), PETG (Polyethylene Terephthalate Glycol), and composite filaments infused with carbon fiber or wood. These materials offer unique properties for specific applications, such as flexibility, transparency, or enhanced strength. While they can be more expensive or difficult to print with, they provide exciting opportunities for innovation.

Considerations for Choosing the Right Material

When selecting a material, consider factors such as the intended use of the printed object, environmental conditions it will be exposed to, and any post-processing requirements. Always take into account the printer's capabilities and whether it supports the chosen material.

By understanding the properties and limitations of each material, you can make an informed decision that aligns with your project's goals and requirements. Experimenting with different materials can also lead to discovering new possibilities and achieving the best results in your 3D printing endeavors.