How 3D Printing Can Accelerate Your Prototype Development in Chicago

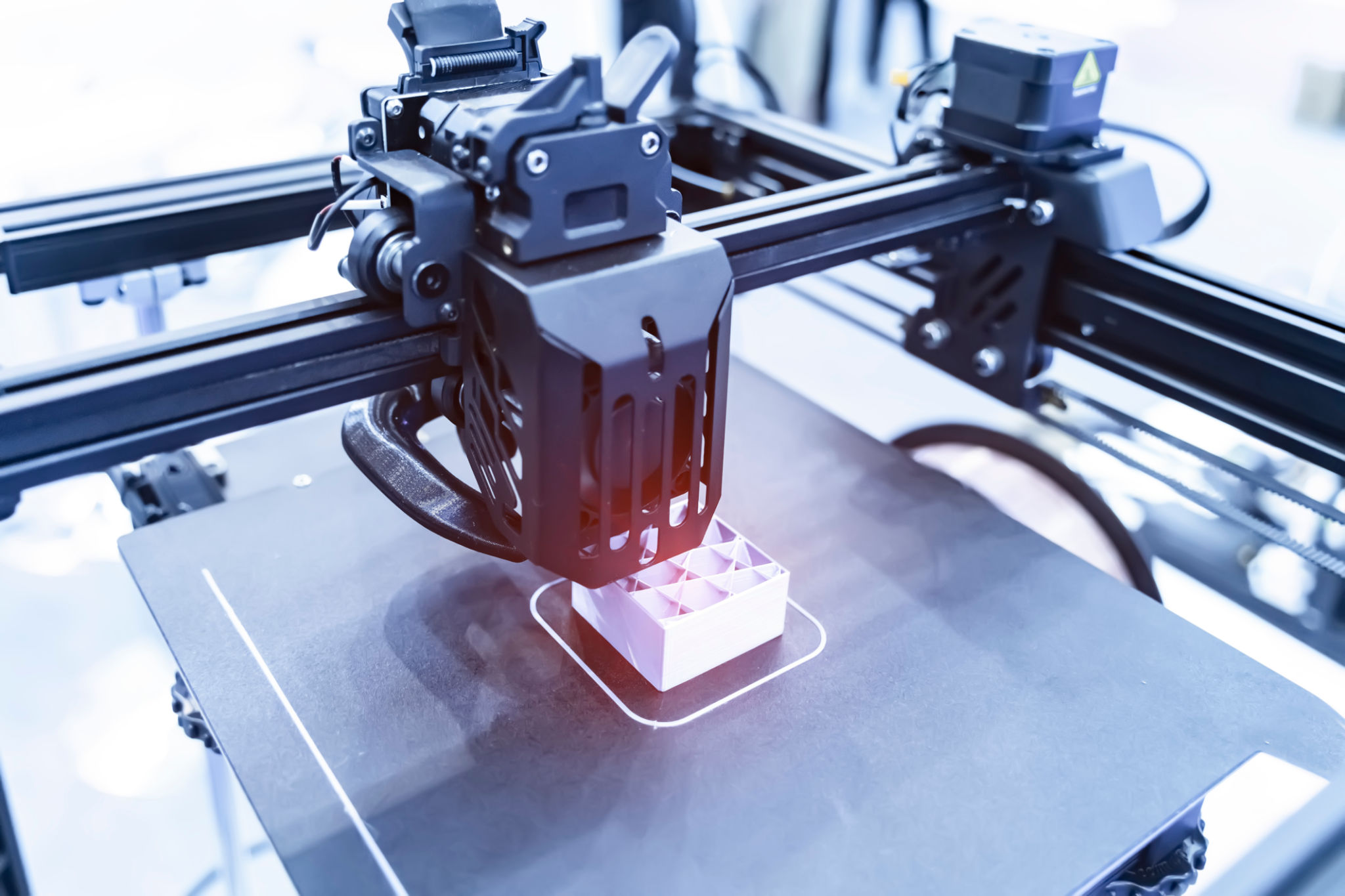

Introduction to 3D Printing in Prototype Development

In the bustling city of Chicago, innovation thrives across various industries. One technological advancement that has significantly impacted product development is 3D printing. This cutting-edge technology offers a myriad of benefits, particularly in accelerating prototype development. By enabling rapid prototyping, 3D printing helps businesses bring their ideas to life faster than traditional methods.

Speed and Efficiency

One of the most compelling advantages of 3D printing in prototype development is its speed. Traditional prototyping methods can take weeks to create a single model. In contrast, 3D printers can produce a prototype within hours, depending on complexity. This swift turnaround allows design teams to iterate quickly, testing and refining their designs with minimal downtime.

Moreover, 3D printing streamlines the production process by eliminating multiple steps typically involved in traditional manufacturing. This efficiency means more time for creativity and innovation, rather than waiting for prototypes to be built.

Cost-Effective Solutions

The cost-effectiveness of 3D printing is another significant benefit. Traditional prototyping often involves expensive tooling and labor costs. With 3D printing, these expenses are drastically reduced. Materials used in 3D printing are generally less costly, and the automated nature of the process reduces labor requirements.

Furthermore, businesses can experiment with different designs without worrying about prohibitive costs. This financial flexibility encourages experimentation and innovation, as companies can afford to explore various iterations before settling on the final design.

Customization and Flexibility

3D printing offers unparalleled customization options, allowing companies to create prototypes tailored to specific requirements. This flexibility is particularly beneficial for industries that require highly specialized components or personalized products. Whether it's a unique architectural model or a custom medical device, 3D printing can accommodate intricate designs that might be challenging for traditional methods.

Design Freedom

The design freedom offered by 3D printing is another reason why it's favored in prototype development. Complex geometries and intricate details that are difficult or impossible to achieve with conventional techniques become feasible with 3D printing. This capability opens up new possibilities in product design and development.

Environmental Impact

As businesses in Chicago and beyond become more environmentally conscious, the sustainability of 3D printing becomes increasingly relevant. Unlike traditional manufacturing methods that often generate significant waste, 3D printing minimizes material usage by building objects layer by layer. This additive process reduces waste and conserves resources.

Additionally, many 3D printing materials are recyclable or biodegradable, contributing to a more sustainable production cycle. Adopting 3D printing can help businesses reduce their carbon footprint while still achieving high-quality results.

Conclusion: Embracing the Future with 3D Printing

In conclusion, 3D printing is revolutionizing prototype development in Chicago by offering speed, cost savings, customization, and environmental benefits. As this technology continues to evolve, its impact on various industries will only grow stronger. For businesses looking to stay ahead in a competitive market, embracing 3D printing is not just an option—it's a strategic necessity.

By leveraging the advantages of 3D printing, companies can accelerate their product development cycles, foster innovation, and ultimately deliver better products to market faster than ever before.