How 3D Printing is Transforming Automation and Robotics in Chicago

In recent years, the intersection of 3D printing, automation, and robotics has sparked a revolution in many industries, and Chicago is no exception. The Windy City is at the forefront of this transformation, leveraging cutting-edge technologies to innovate and streamline manufacturing processes. As these technologies evolve, they are reshaping the landscape of these sectors, offering new opportunities and efficiencies.

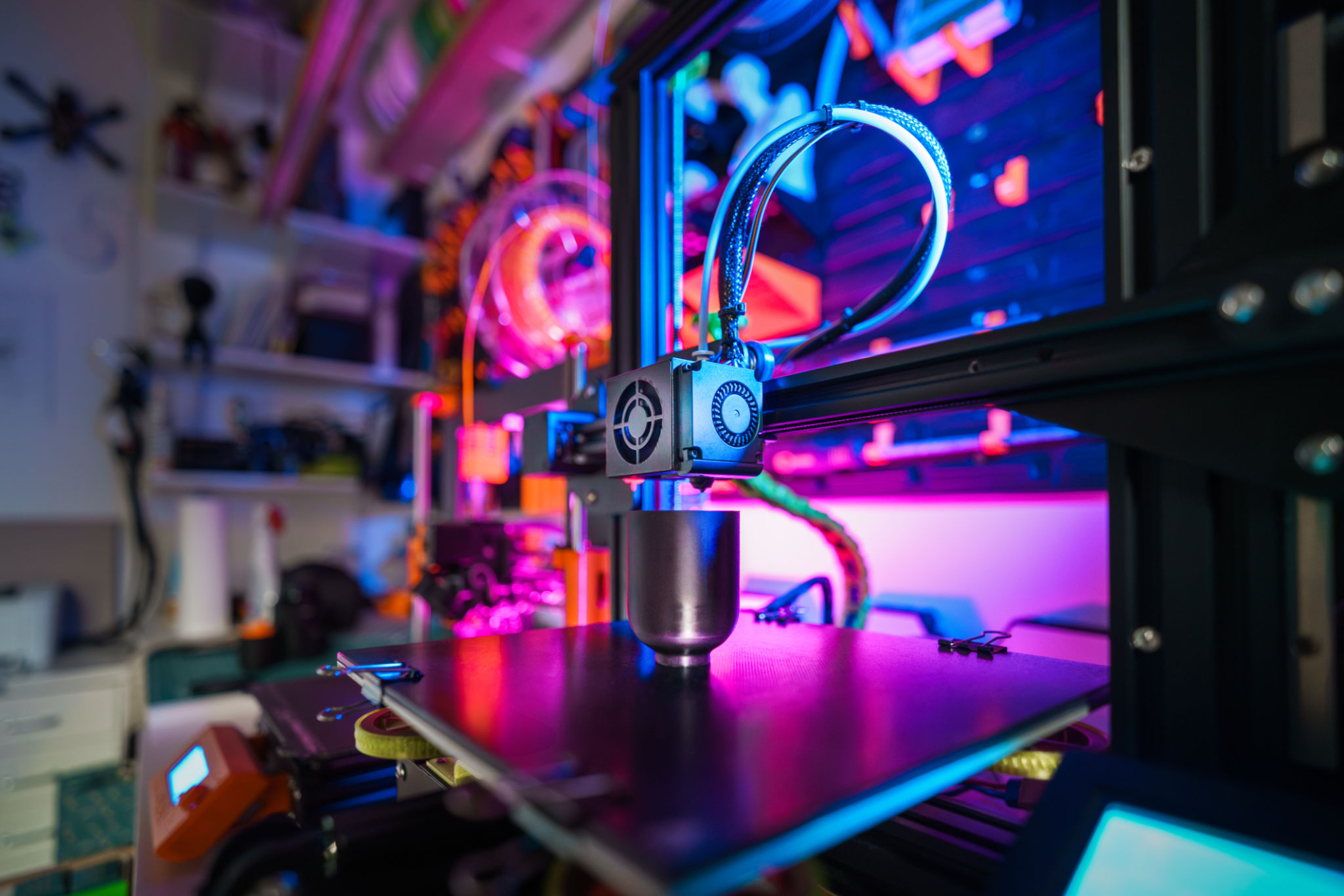

The Rise of 3D Printing in Manufacturing

3D printing, also known as additive manufacturing, is increasingly being integrated into the manufacturing processes in Chicago. This technology allows for the creation of complex geometries that were previously impossible with traditional methods. By layering material precisely where it is needed, companies can reduce waste and improve resource efficiency. This is particularly beneficial in industries like aerospace and automotive, where precision and sustainability are paramount.

Moreover, 3D printing accelerates the prototyping process significantly. What used to take weeks or even months can now be achieved in just a few days. This rapid prototyping capability is invaluable for manufacturers looking to iterate quickly and bring products to market faster than ever before.

Automation Enhancing Efficiency

Automation plays a crucial role in Chicago's push towards smarter manufacturing. By integrating robotics into production lines, companies can achieve higher levels of efficiency and productivity. Robots are capable of working alongside humans, taking on repetitive tasks and allowing human workers to focus on more complex and strategic activities.

In addition to boosting productivity, automation also improves safety in the workplace. By handling dangerous or strenuous tasks, robots help reduce the risk of workplace injuries. This not only enhances employee well-being but also reduces costs associated with accidents and health-related absences.

Synergy Between 3D Printing and Robotics

The synergy between 3D printing and robotics is where true innovation lies. By combining these technologies, Chicago-based companies are able to create highly customized solutions tailored to specific needs. For instance, robotic arms equipped with 3D printing capabilities can repair or replace parts on-the-fly, minimizing downtime and maximizing operational efficiency.

This integration also supports the concept of localized manufacturing. Instead of relying on global supply chains, businesses can produce parts and components on-site, reducing transportation costs and environmental impact. This shift not only enhances supply chain resilience but also promotes sustainability.

Impact on Local Economy

The adoption of 3D printing and robotics is having a profound impact on Chicago's economy. By fostering innovation and creating high-tech jobs, these technologies are driving economic growth in the region. Entrepreneurs and startups are particularly benefiting from this trend, as they can leverage these tools to bring new ideas to life with relatively low overhead costs.

Furthermore, educational institutions in Chicago are partnering with industry leaders to provide training and skills development in these fields. This collaboration ensures a steady pipeline of skilled workers ready to support the evolving needs of the market.

Future Prospects

Looking ahead, the potential for growth in 3D printing and robotics in Chicago is immense. As technology continues to advance, we can expect even greater integration and sophistication in manufacturing processes. Innovations such as AI-driven design and smarter automation systems will likely become more prevalent, further transforming how products are designed and produced.

Chicago is poised to remain a leader in this technological revolution, demonstrating how cities can successfully harness the power of 3D printing and robotics to drive progress and prosperity.