Innovations in FDM 3D Printing: What Chicago Manufacturers Need to Know

The Rise of FDM 3D Printing

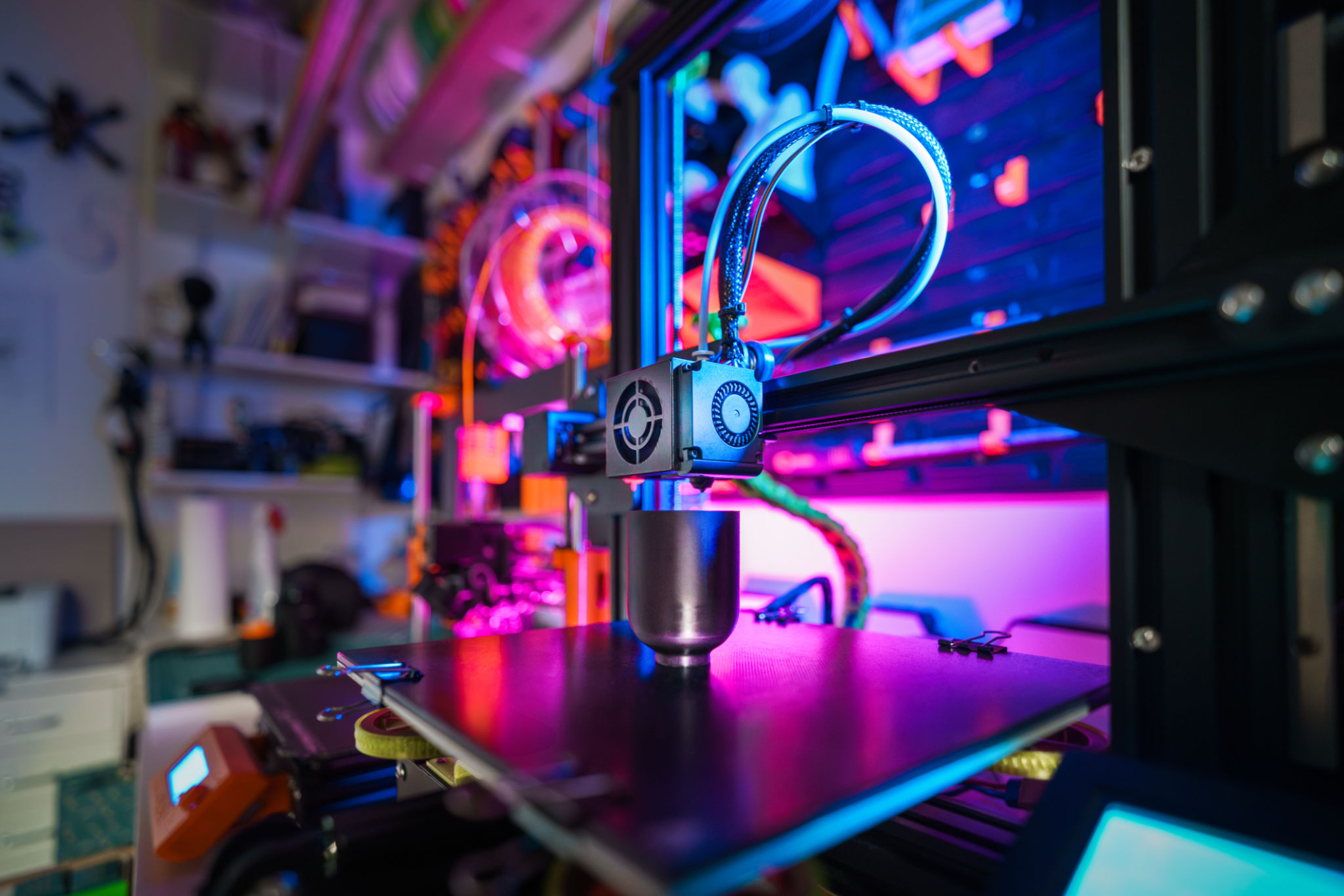

Fused Deposition Modeling (FDM) 3D printing has become a cornerstone in modern manufacturing, particularly for its cost-effectiveness and versatility. Chicago manufacturers, known for their innovation and forward-thinking, are increasingly leveraging FDM technology to stay competitive. As the industry evolves, understanding the latest innovations in this field is crucial for staying ahead.

Material Advancements

Recent advancements in materials have significantly expanded the capabilities of FDM 3D printing. Manufacturers now have access to a wider range of filaments, including high-strength composites and temperature-resistant polymers. These materials enable the production of parts that were previously impossible with traditional manufacturing methods. Chicago businesses can benefit by exploring these new materials to enhance product durability and functionality.

One notable innovation is the development of biodegradable filaments, which align with the growing demand for sustainable manufacturing practices. Adopting eco-friendly materials can not only reduce environmental impact but also appeal to environmentally conscious consumers.

Enhanced Print Quality

The quality of FDM prints has improved dramatically due to innovations in printer technology and software. Enhanced precision and reduced layer lines mean that manufacturers can produce parts with smoother finishes and greater detail. This is particularly important for industries such as aerospace and automotive, where precision is paramount.

Software advancements have also played a critical role. Improved slicing algorithms and real-time monitoring capabilities allow for better control over the printing process, minimizing errors and waste. Chicago manufacturers should consider investing in these advancements to increase efficiency and reduce costs.

Speed and Automation

Speed is a critical factor in manufacturing, and FDM 3D printing is no exception. Recent innovations have focused on increasing print speed without compromising quality. Multi-nozzle systems and faster extrusion technologies are leading the way in this regard, making it feasible to produce large quantities of parts in shorter timeframes.

Automation is another area where FDM printing is making strides. Automated material handling systems and robotic arms are increasingly being integrated into FDM workflows, reducing the need for manual intervention and increasing production efficiency. For Chicago manufacturers, adopting these technologies can significantly boost output while reducing labor costs.

Applications Across Industries

The versatility of FDM 3D printing makes it applicable across various industries. In healthcare, for example, it is being used to create custom prosthetics and surgical models. In the construction industry, FDM technology is being explored for creating architectural models and even structural components.

Chicago's diverse industrial landscape means that there are numerous opportunities to integrate FDM printing into various sectors. By understanding the specific needs of each industry, manufacturers can tailor their 3D printing strategies to maximize impact.

Conclusion: Embracing the Future

As innovations in FDM 3D printing continue to unfold, Chicago manufacturers have a unique opportunity to harness these advancements to drive growth and innovation. By staying informed about new materials, technologies, and applications, businesses can position themselves at the forefront of manufacturing excellence.

Embracing these changes not only enhances operational capabilities but also opens up new avenues for creativity and product development. For Chicago manufacturers, the future of FDM 3D printing is not just about keeping up—it's about leading the way.