Maximizing Efficiency with Low Volume 3D Printing for End Use Parts

Introduction to Low Volume 3D Printing

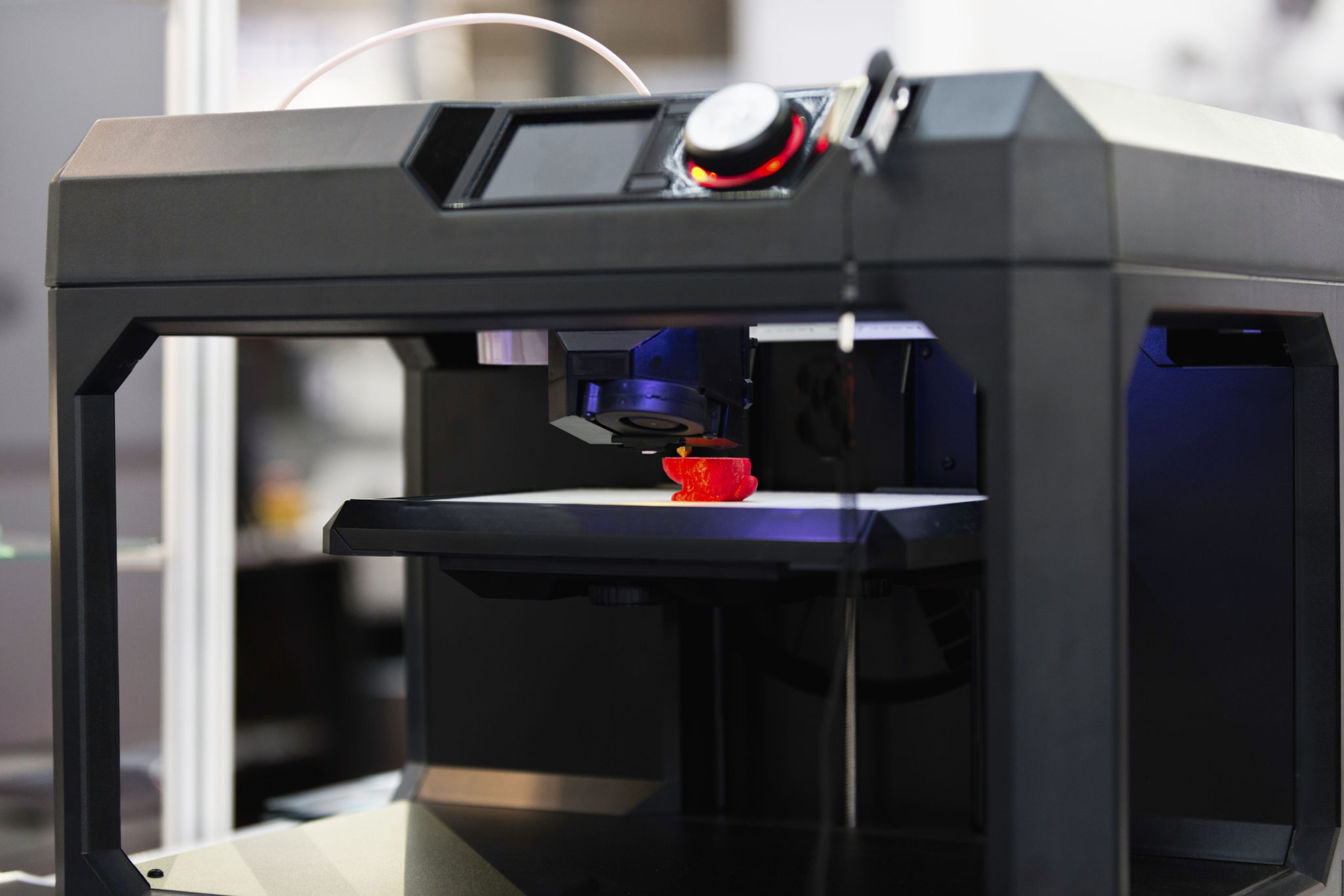

In the rapidly evolving world of manufacturing, low volume 3D printing is emerging as a game-changer for producing end-use parts. This technology offers numerous advantages, including cost-effectiveness, flexibility, and the ability to produce complex geometries. As businesses seek ways to improve efficiency and reduce costs, understanding how to leverage 3D printing for small production runs can provide a significant competitive edge.

Benefits of Low Volume 3D Printing

Cost-Effectiveness

One of the primary benefits of low volume 3D printing is its cost-effectiveness. Traditional manufacturing methods often require expensive tooling and setup costs, which can be prohibitive for small production runs. In contrast, 3D printing eliminates the need for tooling, allowing businesses to produce parts at a fraction of the cost. This is particularly advantageous for startups and small businesses looking to minimize overhead.

Flexibility and Customization

Another advantage of low volume 3D printing is the flexibility it affords. Companies can easily customize parts to meet specific requirements without incurring additional costs. This is ideal for industries where bespoke solutions are required, such as aerospace and medical devices. The ability to quickly iterate and refine designs also accelerates the product development cycle, bringing products to market faster.

Applications in End-Use Parts

Complex Geometries

The ability of 3D printing to create complex geometries is unparalleled. This feature is particularly beneficial for producing end-use parts with intricate designs that would be difficult or impossible to manufacture using traditional methods. Whether it's lightweight lattice structures or internal channels, 3D printing opens up new possibilities for design innovation.

On-Demand Production

Low volume 3D printing also supports on-demand production, allowing companies to produce parts as needed rather than maintaining large inventories. This reduces storage costs and minimizes the risk of obsolescence. Businesses can respond swiftly to changes in demand, ensuring that they meet customer needs without overproducing.

Challenges and Considerations

While there are clear benefits to low volume 3D printing, there are also challenges to consider. Material selection can be limited compared to traditional manufacturing methods, and the mechanical properties of 3D printed parts may not always match those of traditionally manufactured components. Additionally, achieving consistent quality can be challenging, necessitating rigorous testing and quality control processes.

Strategies for Maximizing Efficiency

Choosing the Right Technology

To maximize efficiency with low volume 3D printing, it's crucial to select the right technology for your specific application. Factors such as material requirements, part size, and desired finish will influence the choice of 3D printing method. Investing in the right equipment and expertise can significantly enhance production outcomes.

Streamlining Workflow

Implementing streamlined workflows is essential for optimizing efficiency in 3D printing operations. This includes integrating design software with production hardware, establishing clear communication channels between teams, and automating routine tasks where possible. By refining the workflow, businesses can reduce lead times and improve overall productivity.

Conclusion

Low volume 3D printing offers a multitude of benefits for producing end-use parts, from cost savings to increased design flexibility. By understanding the potential applications and addressing the associated challenges, businesses can unlock new opportunities for innovation and efficiency. As technology continues to advance, the role of 3D printing in manufacturing will undoubtedly expand, providing even more tools for businesses to thrive in a competitive market.