Myths About High-Volume 3D Printing Services Debunked

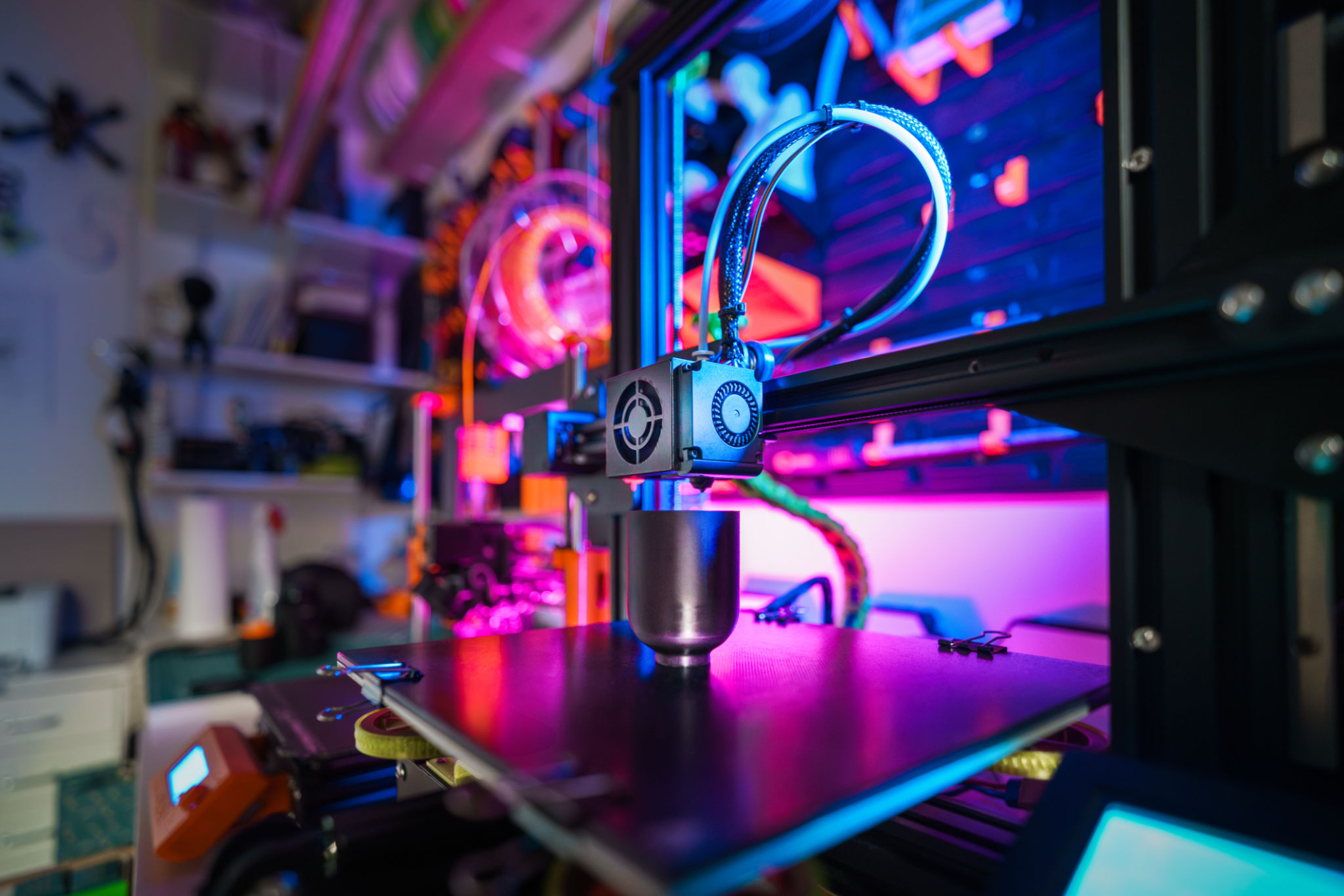

Understanding High-Volume 3D Printing Services

High-volume 3D printing is revolutionizing the manufacturing industry by providing a cost-effective and efficient way to produce large quantities of parts and products. However, despite its growing popularity, there are several myths surrounding this technology that can lead to misunderstandings. In this post, we will debunk some of the most common myths about high-volume 3D printing services.

Myth 1: 3D Printing is Only for Prototyping

One of the most persistent myths is that 3D printing is only suitable for creating prototypes. While it's true that 3D printing is an excellent tool for prototyping due to its flexibility and speed, it has evolved significantly. Today, high-volume 3D printing services can produce end-use products at scale, making it a viable option for full-scale manufacturing.

Industries such as aerospace, automotive, and healthcare are already utilizing 3D printing for production parts. With advancements in materials and technology, 3D printing is capable of meeting stringent quality and performance standards required for mass production.

Myth 2: 3D Printed Parts are Inferior in Quality

Another common misconception is that 3D printed parts are of lower quality compared to those produced using traditional manufacturing methods. However, this is far from the truth. Modern high-volume 3D printers are capable of producing parts with exceptional accuracy and detail.

The quality of 3D printed parts depends largely on the materials used and the expertise of the service provider. Many high-volume 3D printing services offer a wide range of materials, including metals and advanced polymers, that ensure parts meet or exceed industry standards.

Myth 3: 3D Printing is Too Slow for Large-Scale Production

There's a belief that 3D printing is inherently slower than traditional manufacturing processes such as injection molding or CNC machining, making it unsuitable for large-scale production. While it is true that individual prints can take longer, the technology has advanced to allow for rapid production at scale.

High-volume 3D printing services utilize multiple printers simultaneously, often operating around the clock to meet large orders. Additionally, new technologies such as continuous liquid interface production (CLIP) and multi-jet fusion have dramatically increased the speed of production.

Myth 4: 3D Printing is Too Expensive

Cost concerns are often cited as a barrier to adopting high-volume 3D printing services. However, when considering the total cost of production, 3D printing can be more cost-effective than traditional methods. There are no tooling costs, minimal waste, and the ability to produce complex geometries without additional expense.

Moreover, the ability to produce on-demand reduces inventory costs and shortens supply chains. As technology continues to evolve, the cost of materials and printers is expected to decrease further, making high-volume 3D printing even more affordable.

The Future of High-Volume 3D Printing

As we continue to debunk myths surrounding high-volume 3D printing services, it becomes clear that this technology offers significant advantages in terms of flexibility, speed, and cost. Companies willing to embrace these advancements are positioned to benefit greatly in terms of innovation and competitiveness.

The future of manufacturing lies in the ability to quickly adapt and respond to market demands. High-volume 3D printing provides that agility, allowing businesses to produce customized products faster and more efficiently than ever before.