Overcoming Common Challenges in On-Demand 3D Printing for Engineers

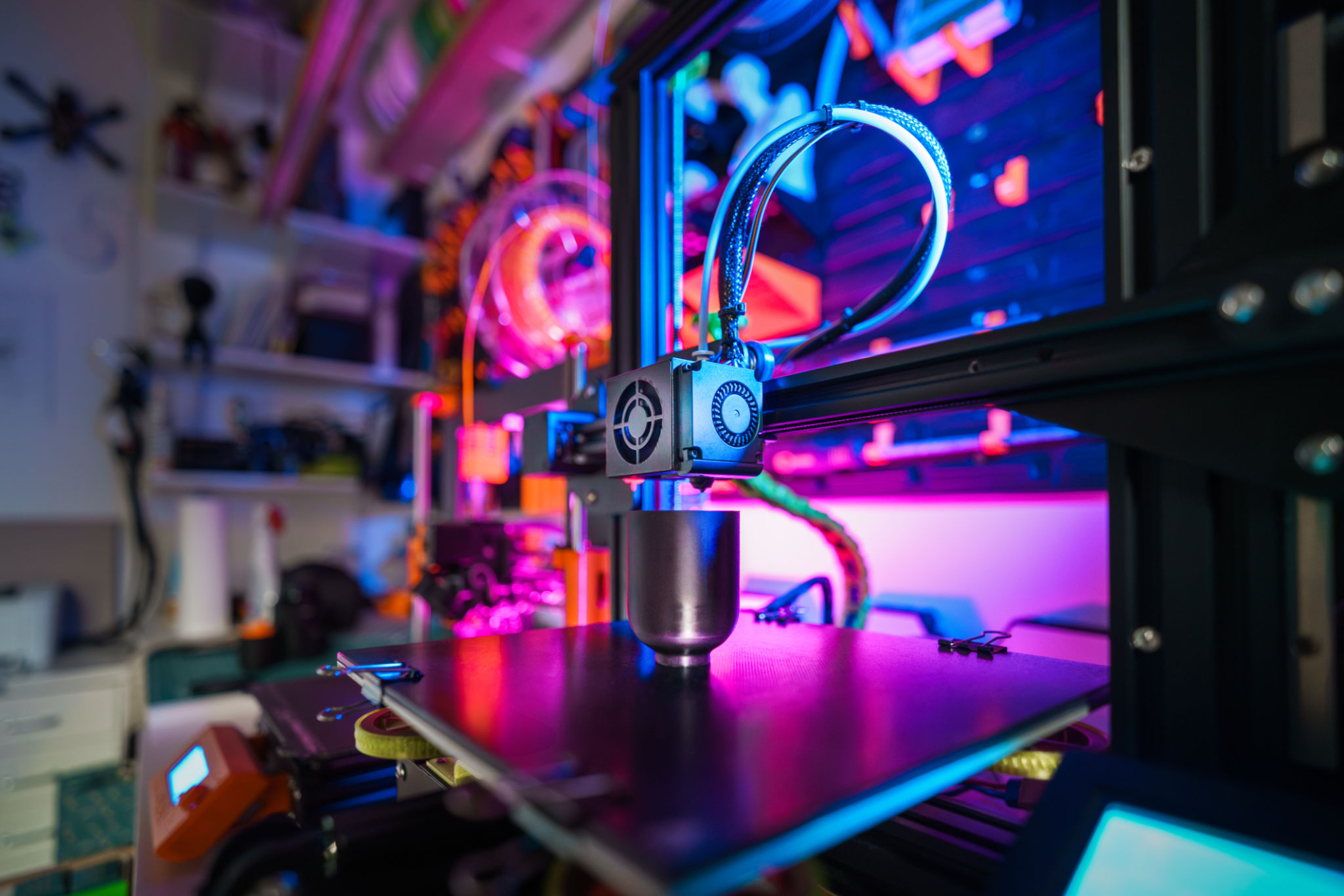

Understanding the Basics of On-Demand 3D Printing

On-demand 3D printing, also known as additive manufacturing, is a revolutionary technology that allows engineers to create prototypes and final products quickly and efficiently. This process involves adding material layer by layer to build a three-dimensional object from a digital file. While this technology offers numerous advantages, engineers often face several challenges in its implementation.

Material Selection and Quality Control

Choosing the right material is crucial in 3D printing. Engineers must consider factors such as strength, flexibility, and temperature resistance, which vary significantly across materials like plastics, metals, and ceramics. Ensuring material quality and consistency is another challenge, as any variation can lead to defects in the final product.

To overcome these challenges, engineers should work closely with material suppliers to understand the properties of each material and conduct thorough testing before full-scale production. Implementing stringent quality control measures can also help in maintaining consistency and reliability in 3D-printed products.

Design Complexity and Software Limitations

One of the significant advantages of 3D printing is its ability to produce complex geometries that traditional manufacturing methods cannot achieve. However, designing for 3D printing requires a different approach. Engineers often face difficulties in using CAD software to create designs that are both functional and optimized for the printing process.

To address this, engineers should invest time in learning advanced CAD software features and stay updated with the latest design tools. Collaborating with experienced designers can also provide valuable insights and innovative solutions for complex projects.

Cost Management in 3D Printing

The cost of materials, equipment, and labor can add up quickly in on-demand 3D printing projects. Engineers need to manage these costs carefully to maintain profitability while delivering high-quality products. Implementing cost-effective strategies without compromising on quality is essential.

One effective approach is to use simulation tools to predict production costs and identify potential savings. Additionally, engineers can explore alternative materials or adjust design parameters to reduce costs while still meeting project requirements.

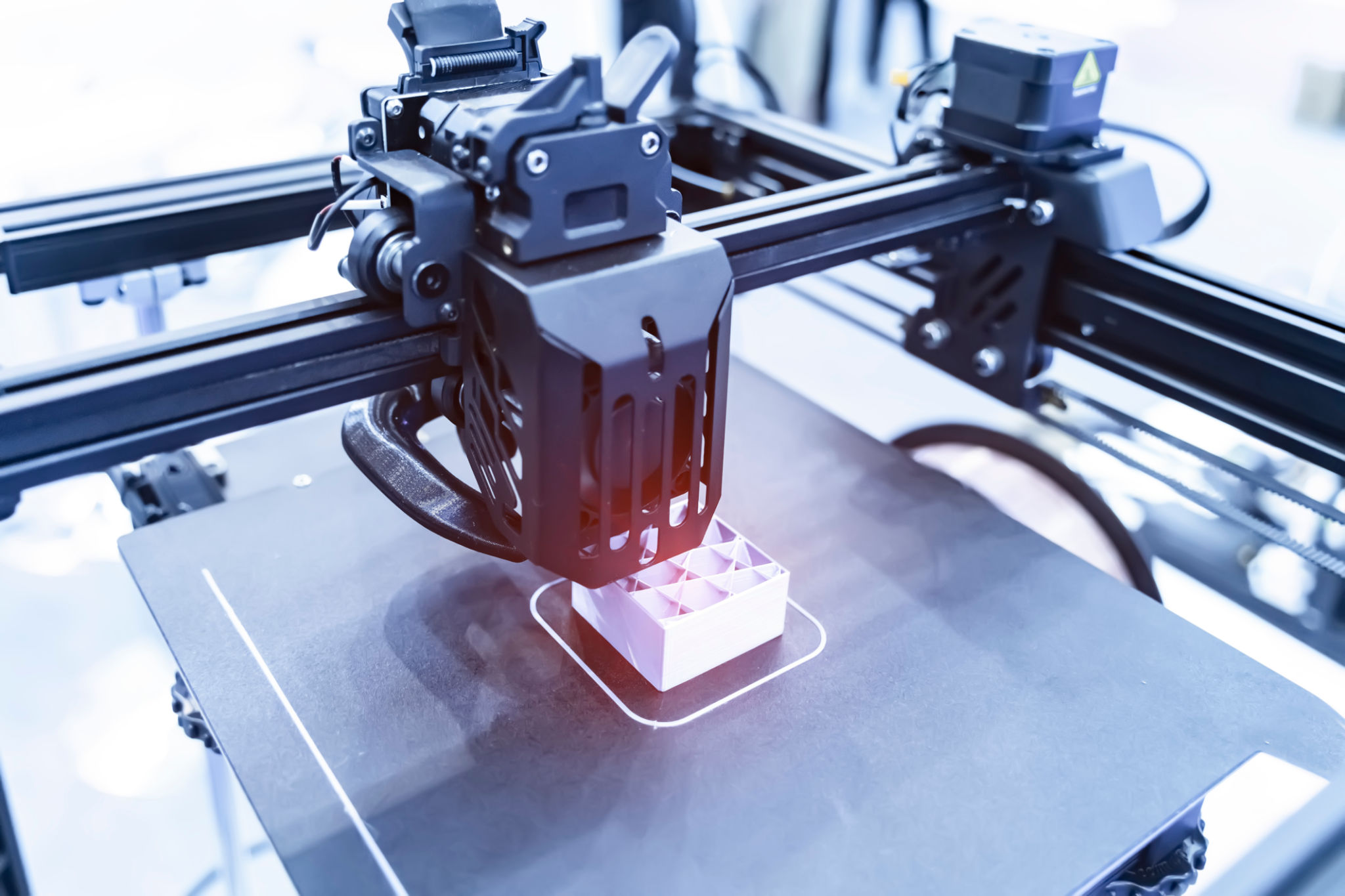

Post-Processing and Finishing

After a 3D print is completed, post-processing is often required to enhance the product's appearance or performance. This step can include removing support structures, sanding, painting, or applying coatings. Each of these processes introduces its own set of challenges.

To streamline post-processing, engineers should plan for these steps during the initial design phase, selecting designs and materials that minimize post-processing needs. Investing in automated post-processing equipment can also save time and reduce labor costs.

Ensuring Scalability and Customization

While 3D printing excels at producing small batches or customized products, scaling up production can be challenging. Engineers must balance customization with the need for efficient mass production. This often requires rethinking production lines and implementing modular designs that can be easily adjusted.

To overcome scalability challenges, engineers can adopt a hybrid manufacturing approach that combines 3D printing with traditional methods. This allows for greater flexibility and efficiency in meeting varying production demands.

The Future of On-Demand 3D Printing

The field of on-demand 3D printing is rapidly evolving, with advances in materials, technology, and processes continually emerging. Engineers must stay informed about these developments to remain competitive and leverage new opportunities.

Continuous education and collaboration with industry experts can help engineers stay ahead of the curve. By embracing innovation and overcoming common challenges, engineers can fully realize the transformative potential of on-demand 3D printing in their projects.