Rapid Prototyping vs. Traditional Prototyping: Which is Right for Your Project?

Understanding Prototyping

Prototyping is a crucial step in the product development process, allowing designers and engineers to bring their ideas to life and test them before full-scale production. There are two main approaches to prototyping: rapid prototyping and traditional prototyping. Each has its own set of advantages and challenges, and choosing the right one depends on your project's specific needs.

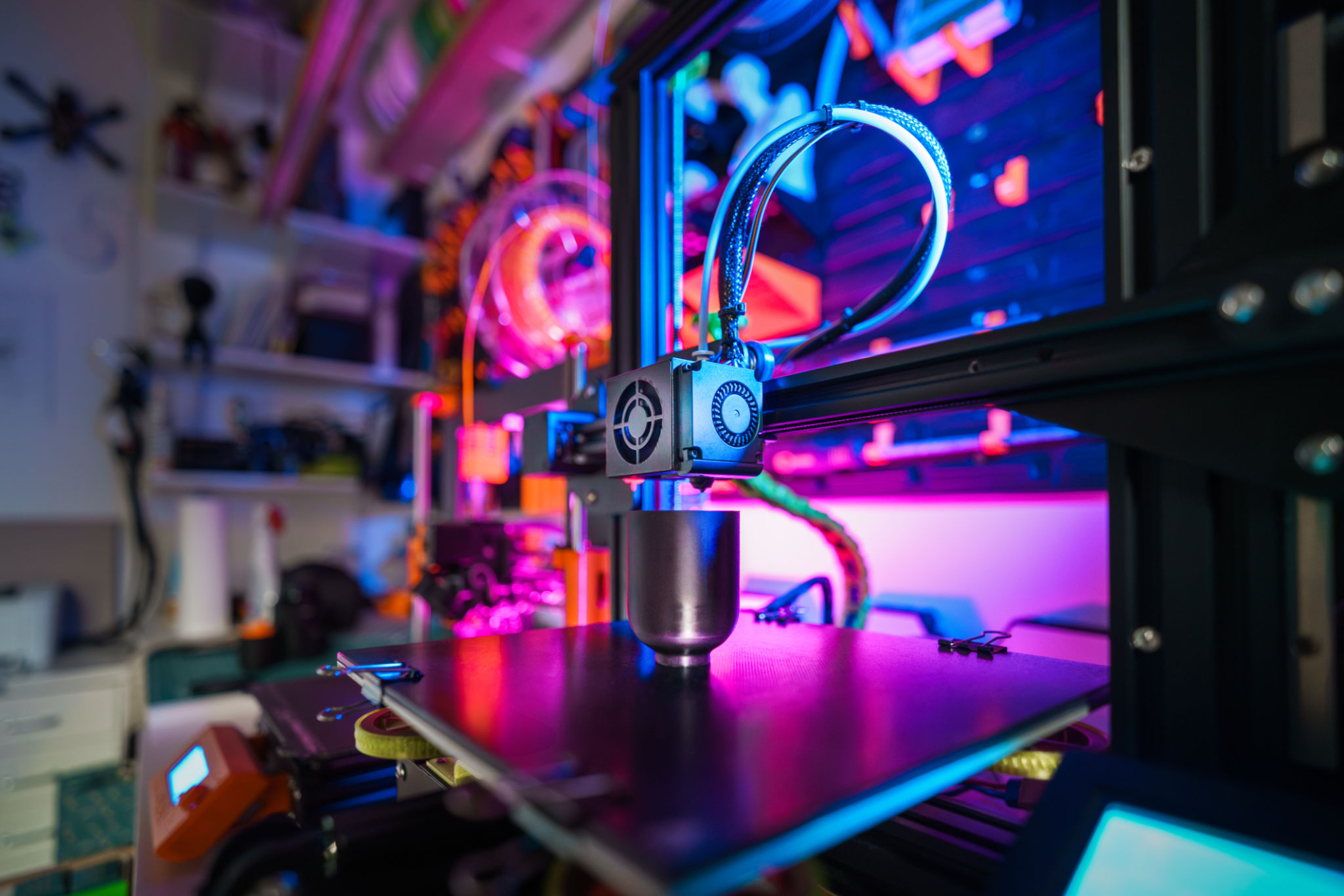

Rapid prototyping leverages advanced technologies such as 3D printing, CNC machining, and laser cutting to quickly fabricate a scale model of a physical part or assembly. On the other hand, traditional prototyping typically involves more manual processes and may use materials like clay, wood, or metal to create a prototype.

Speed and Flexibility

One of the most significant advantages of rapid prototyping is the speed at which prototypes can be developed. With rapid prototyping, you can move from design to prototype in a matter of days or even hours, depending on the complexity of the project. This speed allows for quick iterations and adjustments, making it easier to refine and improve the design.

Traditional prototyping, while generally slower, offers a different kind of flexibility. It allows for more hands-on adjustments and modifications during the creation process. This approach can be beneficial for projects where tactile feedback and manual adjustments are crucial.

Cost Considerations

Cost is another important factor when deciding between rapid and traditional prototyping. Rapid prototyping can be more cost-effective for projects that require multiple iterations, as it reduces the need for labor-intensive manual work. The use of automated machinery decreases production time, thus lowering overall expenses.

However, the initial investment in rapid prototyping equipment and materials can be high. Traditional prototyping might be more cost-effective for simple designs or when there's no need for frequent iterations since it often uses readily available materials and tools.

Material Options

Rapid prototyping provides a wide range of material options, from plastics and resins to metals and ceramics. This versatility allows for prototypes that closely mimic the final product's properties, which is essential for testing functionality and performance.

Traditional prototyping may have limitations in terms of available materials, but it can excel in situations where the feel and aesthetic of the prototype are more critical than its performance. Materials like wood or clay can be easily shaped and modified to achieve the desired look.

Precision and Detail

When it comes to precision and detail, rapid prototyping is often superior due to its use of advanced technologies that can produce intricate designs with high accuracy. This is particularly beneficial for complex projects that require detailed parts or assemblies.

While traditional prototyping might not match the precision of rapid methods, it provides an opportunity for artisanship and creativity. Designers can apply hands-on skills to achieve specific aesthetic details that machines may not replicate easily.

Choosing the Right Method for Your Project

Deciding whether to use rapid or traditional prototyping depends largely on your project's specific requirements. If your project demands quick iterations, high precision, and complex geometries, rapid prototyping might be the best choice.

Conversely, if your project benefits from tactile feedback, manual adjustments, or involves simpler designs, traditional prototyping could be more suitable. Weighing these factors will help you determine which method aligns best with your project's goals.