The Ultimate Guide to Designing Strong FDM Parts with ABS and PETG

Introduction to FDM Printing with ABS and PETG

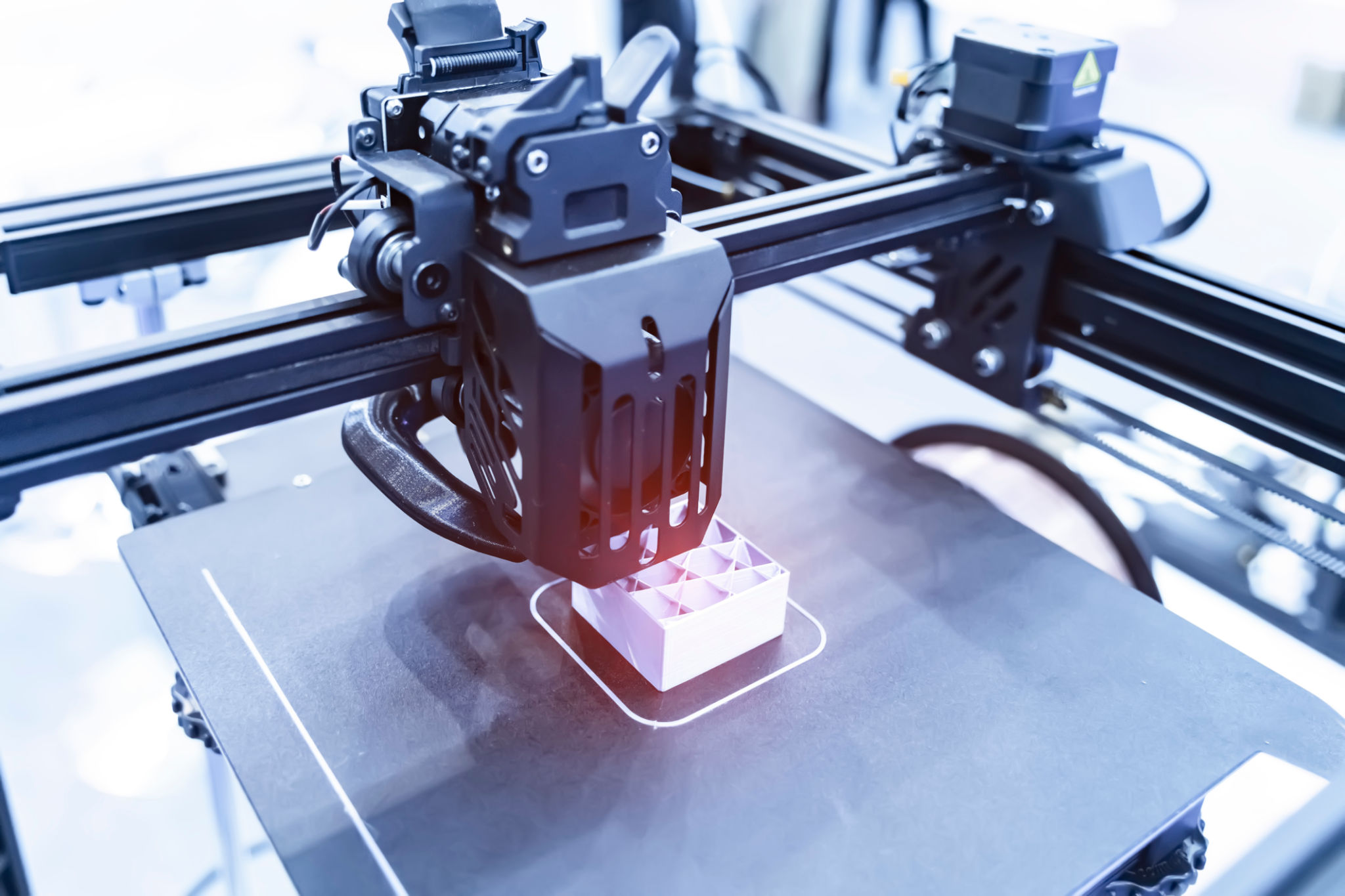

Fused Deposition Modeling (FDM) is one of the most popular 3D printing technologies due to its affordability and versatility. When it comes to choosing materials, ABS and PETG are among the top contenders for creating durable and functional parts. Understanding the characteristics and best practices for each can significantly enhance your printing outcomes.

Understanding the Basics of ABS

ABS (Acrylonitrile Butadiene Styrene) is renowned for its strength and impact resistance. It is ideal for parts that require durability. However, ABS can be tricky to print due to its tendency to warp. To mitigate this, it's crucial to use a heated bed and an enclosed printing environment to maintain consistent temperatures.

Moreover, ABS emits fumes during printing, so ensure your workspace is well-ventilated. Post-processing with acetone vapor can also enhance the surface finish of ABS parts, giving them a smooth and glossy appearance.

Mastering PETG Printing

PETG (Polyethylene Terephthalate Glycol) combines the best of ABS and PLA. It offers strength and flexibility while being easier to print than ABS. PETG is less prone to warping, making it suitable for larger parts.

When printing with PETG, use a moderate bed temperature and ensure the print surface is clean. Unlike ABS, PETG doesn't emit strong odors, making it more user-friendly for home environments. However, be mindful of its tendency to string; optimizing retraction settings can help reduce this.

Designing for Strength and Durability

To design strong parts, consider the following:

- Layer Height: A smaller layer height can increase part strength but may extend print time.

- Infill Density: Higher infill percentages contribute to stronger parts.

- Wall Thickness: Thicker walls can provide additional strength and resilience.

Optimizing Print Settings

Both ABS and PETG require fine-tuning of print settings for optimal results. For ABS, maintain bed temperatures between 90-110°C and extruder temperatures between 210-250°C. For PETG, a bed temperature of 70-85°C and an extruder temperature of 230-250°C are recommended.

Incorporating a brim or raft for ABS can help reduce warping. For PETG, adjust the retraction settings to minimize stringing and oozing.

Post-Processing Techniques

Post-processing can enhance the aesthetics and functionality of your FDM parts. For ABS, acetone vapor smoothing is a popular method to achieve a polished finish. Sanding and painting can also be used to refine the appearance of both ABS and PETG prints.

PETG can be sanded or polished with a heat gun for a glossy finish. Always test these techniques on a small section first to ensure desired results.

Conclusion

Designing strong FDM parts with ABS and PETG involves understanding each material's properties and applying best practices in design and printing. By optimizing settings and utilizing effective post-processing techniques, you can create parts that are not only functional but also visually appealing. With practice and attention to detail, you can master the art of 3D printing with these versatile materials.