Unlocking the Potential of Industrial FDM Printing in Chicago: A Comprehensive Guide

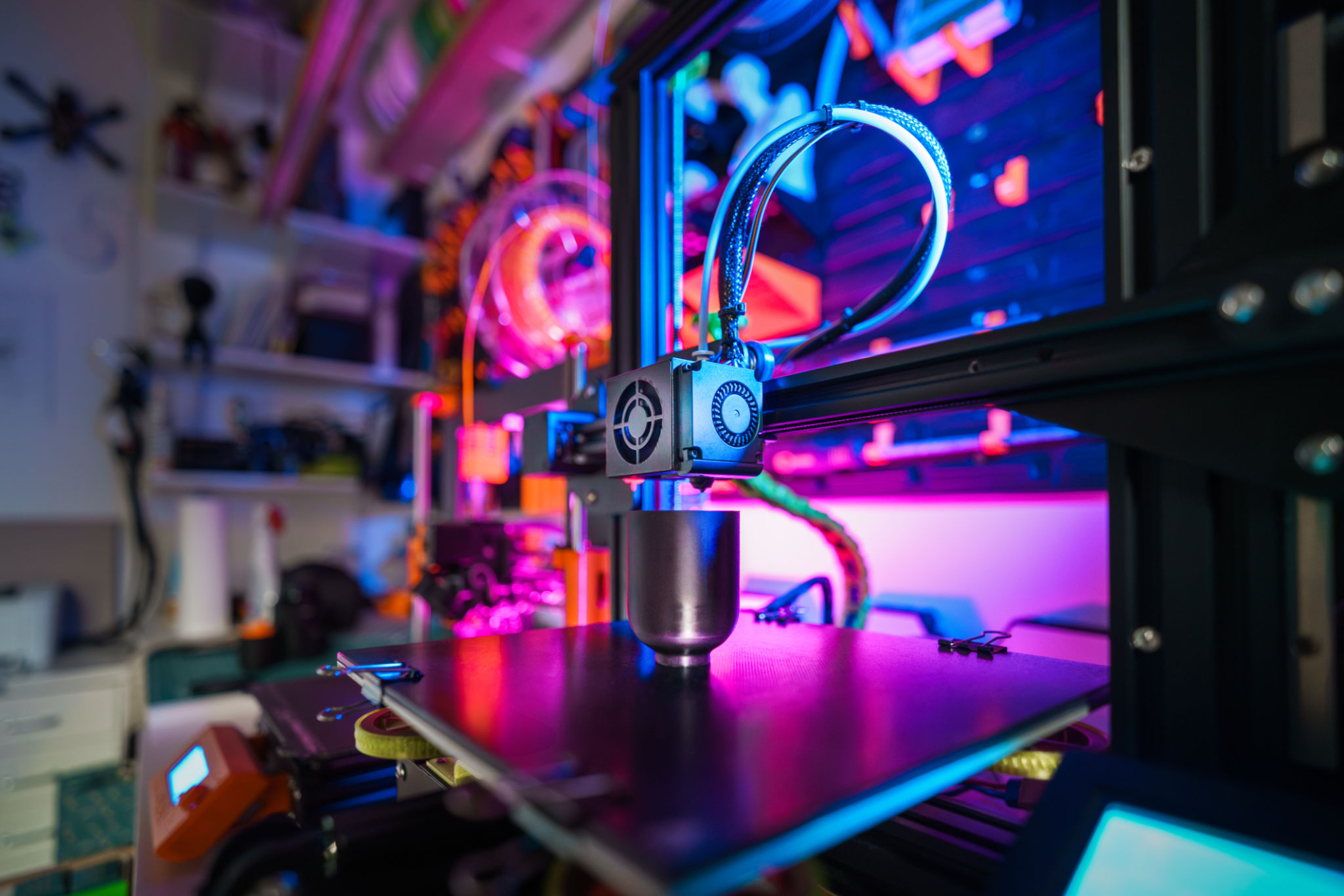

Introduction to Industrial FDM Printing

In recent years, industrial Fused Deposition Modeling (FDM) printing has transformed the manufacturing landscape in Chicago, offering businesses numerous advantages, from cost efficiency to customization. As the technology continues to evolve, understanding its potential can be a game-changer for companies looking to innovate and stay ahead of the competition.

What is FDM Printing?

FDM printing is a type of additive manufacturing process that creates parts by extruding thermoplastic filaments layer by layer. This method is widely used for producing prototypes, as well as end-use parts, due to its ability to create complex geometries with precision and speed. The technology's versatility makes it an attractive option for industries ranging from aerospace to healthcare.

Benefits of Industrial FDM Printing

One of the most significant benefits of industrial FDM printing is its ability to reduce production costs. By using fewer materials and minimizing waste, businesses can achieve significant savings. Additionally, FDM printing allows for rapid prototyping, enabling companies to iterate quickly and bring products to market faster.

Customization is another key advantage. With FDM printing, businesses can produce bespoke designs tailored to specific customer needs without the constraints of traditional manufacturing methods. This level of customization can lead to higher customer satisfaction and increased competitiveness.

Applications in Various Industries

Industrial FDM printing is making waves in several sectors. In the automotive industry, for instance, manufacturers use it to create lightweight components that improve vehicle efficiency. Similarly, in healthcare, FDM printing enables the production of custom medical devices that enhance patient care.

The aerospace industry also benefits from FDM printing's ability to produce complex parts that meet stringent specifications. This capability ensures high performance while reducing overall production times and costs.

Choosing the Right Materials

Selecting the appropriate material is crucial for successful FDM printing. Common materials include PLA, ABS, and Nylon, each offering distinct properties suitable for different applications. PLA is known for its ease of use and biodegradability, while ABS provides strength and durability. Nylon, on the other hand, offers flexibility and resistance to wear and tear.

Challenges and Considerations

While industrial FDM printing offers numerous benefits, it also presents challenges. One of the primary concerns is ensuring consistent quality across prints. Variations in temperature and humidity can affect the final product, making it essential to maintain controlled environments during production.

Another consideration is the initial investment in equipment and training. Businesses need to weigh these costs against the long-term savings and advantages that FDM printing can provide.

The Future of FDM Printing in Chicago

As technology advances, the potential for industrial FDM printing in Chicago continues to grow. With ongoing research and development, we can expect even greater improvements in speed, material options, and cost-effectiveness. This progression will further solidify FDM printing's role as a pivotal tool in modern manufacturing.

Businesses that embrace this technology are likely to gain a competitive edge by enhancing their production capabilities and meeting the increasing demand for customized products.